IoT

How Industrial IoT Architecture Enhances Decision-Making

How can sophisticated IIoT architecture leverage physical signals to help you achieve the most impressive business results?

The Internet of Things is not only a refrigerator slightly smarter than the owner, capable of not forgetting to order the milk when the previous package is empty. For “data civilians” – people who know nothing of development, the Internet of Things is a "swear word", like blockchain, machine learning, and Big Data. And popular explanations of what IoT is usually offer primitive everyday examples of coffee makers turning on by timer or futuristic fantasy concepts of "smart cities." In simplest terms, IoT is a four-tier system that intertwines

- Connected devices (sensors, terminals)

- Networks through which they interact

- IoT platforms

- Applications for end users

to offer humans a next-level analytical toolkit.

Engineering and Black Magic: What is IoT actually made of?

The concept of IoT (Internet of Things) has been a solid part of the technical and digital narrative for years now, especially in areas of business that, at the least, touch the IT universe. However, many people still confuse the Industrial IoT Architecture with the automation architecture, where the main task is obtaining information from sensors and controlling or managing hardware based on the acquired data. We’ve created this post to unveil how Industrial IoT architecture helps business transform signals from industrial sensors into solid business decisions.

In terms of technology and architecture IoT system should account for several elements at once:

- “Things”: "thing" - an object equipped with a sensor for collecting data and an activator that executes commands received from the network.

- Gateways: data exchange between things and the Cloud occurs through gateways, in which data is pre-processed to reduce traffic between the gateways and the Cloud.

- Cloud gateways compress data and provide security during data transmission from field gateways, cloud servers, and protocol compatibility.

- Data streaming processor: ensures efficient transmission and integrity of input data to data lake and control applications.

- The data lake stores data generated by connected Iiot devices in their native format. When data is used in insights, it is retrieved from the data lake and loaded into the big data warehouse.

- Big data warehouse: filtered and processed data for subject analysis is retrieved from the big data warehouse. In addition, it stores contextual information about things and sensors (for example, about the sensor's location) and commands sent to the actuators.

- Data analytics uses data from big data warehouses, identifies trends, and makes subject analyses. Performs visualization of the results of subject analysis and develops ways to improve the system's efficiency with things. In addition, the correlations found help in making managerial decisions by people.

- Machine learning: ml and the models that ml generates enable the creation of more accurate and efficient models for control applications. The models are regularly updated based on historical data accumulated in the big data warehouse. When data analysts validate the applicability and effectiveness of models, the new models are used by management applications.

At first glance, IoT architecture includes two incompatible constructs: on the one hand, numerous peripheral IIot devices with low computing power and high response rate to events. And on the other hand, cloud servers with increased computing power for processing an extensive array of data, their storage, and classification, often with elements of machine intelligence and analytics.

These two worlds use completely different principles of construction and internal architecture. As a result, they look incompatible, and today few specialists in the labor market are equally familiar with Embedded and Cloud solutions. But in this knowledge lies the power that unites two, at first glance, completely unrelated technologies. And their integration's magnificent synergistic effect gives businesses an unfair advantage.

The challenge of creating Industrial IIoT solution: The secret of successful design and development

Predictably, everything starts with sensors. Moreover, the better the sensor is suited to perform its task, the more effective the system will be furthered. This is a kind of "cornerstone" of the system. It is important to note that the sensor registers a change in the environment, not its static state.

Applications, analytics, data management, Integration, and Infrastructure

Predictably, everything starts with sensors. Moreover, the better the sensor is suited to perform its task, the more effective the system will be furthered. This is a kind of "cornerstone" of the system. It is important to note that the sensor registers a change in the environment, not its static state.

- Data storage. Information storage should occur at the peripheralIIoTdevice level and in the Cloud. The peripheral device saves its program, settings, and state and temporarily stores information from sensors until it is guaranteed to be transferred to the Cloud. Cloud data storage is prominent and does not require explanation, at least within the framework of this article.

- Security and authorization. Each peripheralIIoTdevice must be authorized in the system and individually. This is a separate topic, which is also beyond the scope of this article.

- Queues and pipeline. A separate architecture category transfers information throughout the system inside peripheral devices, in the Cloud, and between them.

How to make the best digital cake: What are the IoT layers of an Industrial IoT architecture?

IoT architecture is like a big awesome birthday cake. It can have as many or as few IoT layers as you want. But at a high level, it should include at least four essential IoT layers.

- Applications and analytics: This is the piece that processes and displays information collected via IIoT. It includes analytics tools, AI and machine learning, and visualization capabilities. Technologies for this component range from traditional analytics and visualization packages, such as R, IBM SPSS, and SAS, to specialized IIoT tools and dashboards from cloud providers, such as Amazon, Google, Microsoft, Oracle, and IBM, as well as application suite vendors, including SAP and Salesforce.

- Infrastructure: This includes physical devices – IIoT sensors, which capture information, and actuators, which control the environment. It also consists of the network on which the sensors or actuators reside. Typically, though not always, this is a wireless network, such as Wi-Fi, 4G, or 5G.

- Integration: This component ensures that the applications, tools, security, and infrastructure integrate effectively with existing company-wide ERP and other management systems. Providers include the software mentioned above, cloud IoT layers, and a range of open source and middleware providers, such as Oracle Fusion Middleware, LinkSmart, Apache Kafka, and DynThings Open Source IIoT platform.

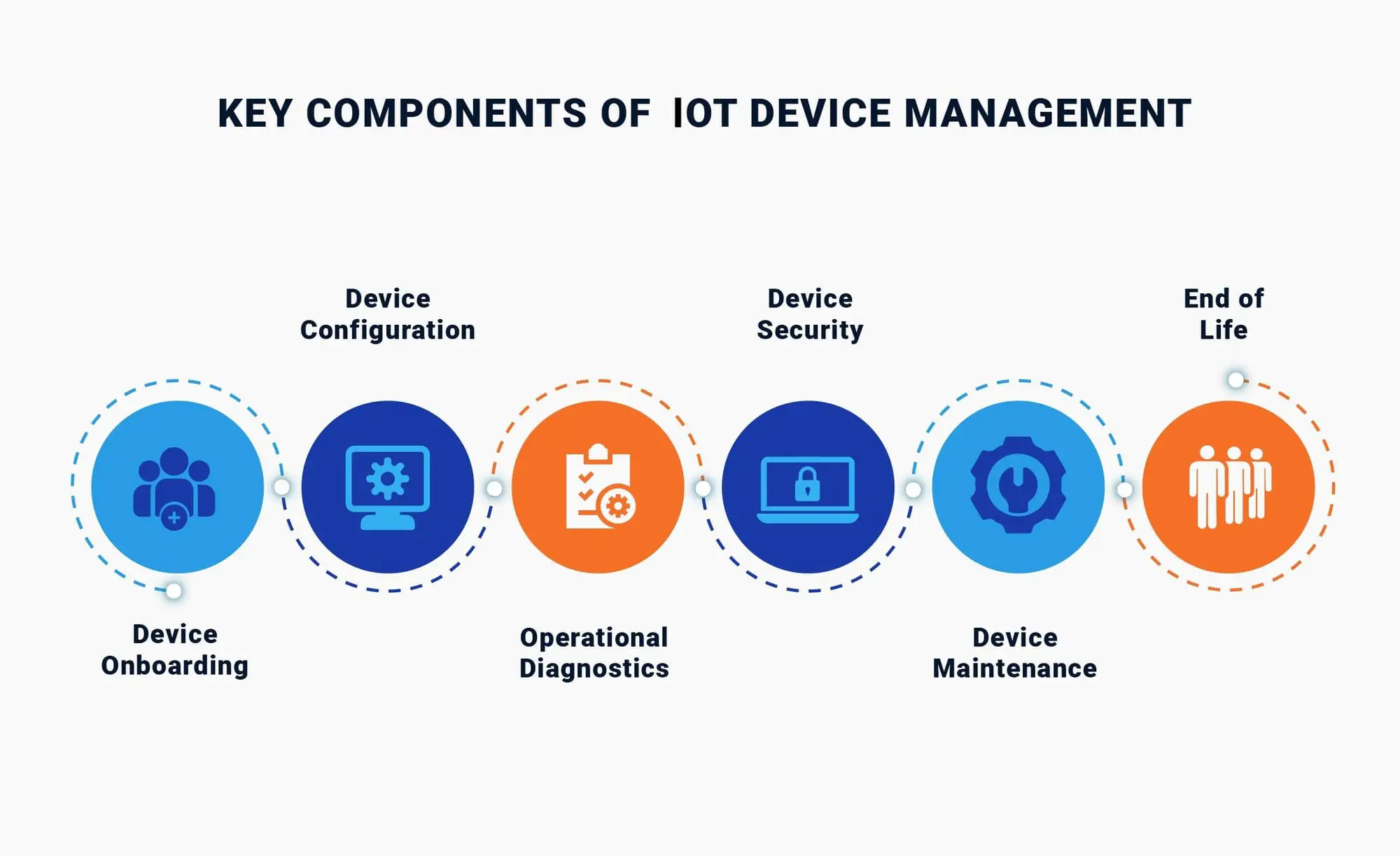

- Security and management: IIoT security includes securing the physical components of the system via firmware and embedded security providers, such as Azure Sphere, LynxOS, Mocana, and Spartan. Traditional security vendors, such as Forescout, Symantec, and Trend Micro, also offer packages that focus on securing IIoT.

Industrial IoT architecture topology differs from the usual layer model. This is not a linear and more complex flow graph. Some components are optional and may not be present in a particular solution class. Two types of logic can be present - M2M and M2P (machine to person).

The IIoT solution has two physical locations - the first is the end (peripheral) IIoT devices, and the second is in the Backend data center on servers or in the Cloud. At the same time, this is not the classic client-server application architecture.

Physical Layer: The great diversity of IoT devices used in the industrial environment

Sensors are divided into active - emitting signals and receiving reflection; and passive - working only on reception. Naturally, the latter win significantly in terms of energy consumption. Most sensors are based on the reception of waves:

- Sound

- Ultrasonic

- Light of various ranges

- Thermal

However, there is a category of sensors based on changes in their physical characteristics, such as:

- Inductance

- Capacitance

- And pressure

In our experience, the best results are obtained from several sensors, such as a PIR detector and a capacitive motion sensor.

Virtual Level: The real-time requirements specific to industrial applications

Industrial IoT applications often need real-time data from IoT devices. For instance, some apps display telemetry or alert data they obtain from devices. That is why the next logical step in developing an industrial IoT architecture is transferring the data to the Cloud, at the server, or sometimes both.

The switch redirects the received information to various objects, classifying tags. These objects can be servers, queues, lambdas, or just storage. Until now, work has been carried out with information from a specific peripheral IIoT device and is no different from the work of automated control systems. However, at the next level, integration, a qualitative difference begins. Information from various peripheral devices is summarized by tags of the same type. At the same time, the types of peripheral IIoT devices themselves can even be different. The tags must fall into a single point responsible for receiving the corresponding event - the tag.

Talking about the "next level," we simply must mention the option of information from all objects being summarized by tags systematized by the Analytical block. It contains the main logic or, if we may say so, “the brains” of the system. Those could be powered by AI, Machine Learning algorithms, or alike. Finally, the result of the "Analytical block" work is transferred to the "Presentation block" for displaying to the user. This may look like sending a message to a mobile device.

Since the IIoT system is distributed and connected by an unreliable communication channel, it is necessary to have mechanisms for guaranteed information delivery. Repeated transmission attempts are made if it is impossible to transfer information from the peripheral IIoT devices to the Cloud. The same should happen on the other side. For these purposes, a block of the Virtual representation of the peripheral device is introduced, into which information is written for transmission to the peripheral IIoT device or its new state. Often this is just a text file, but there may be a more precise representation model. Various input chain modules can initiate changes to the Virtual View module.

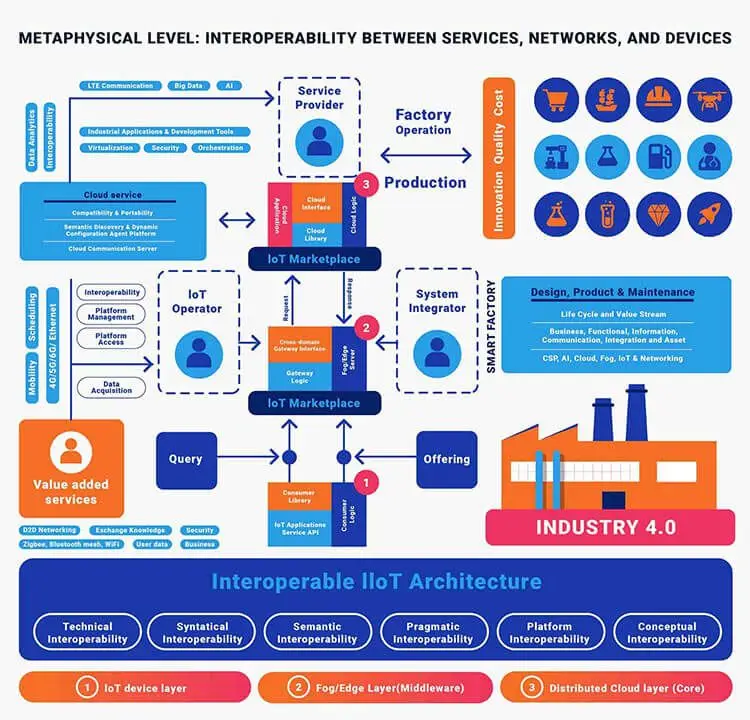

Metaphysical Level

Typical architecture in production environments includes numerous devices, sensors, and gateways that potentially communicate via different protocols. Each entity provides its data and, through direct bidirectional connections, allows it to control the data. This design works best when integrating only a few IIoT systems or elements. However, it leads to a difficult-to-maintain architecture with a more significant number of components, especially if they are hardwired. Modern industrial IoT architecture s requires flexibility.

A recent McKinsey study estimates that a 40% share of the potential economic value of the IIoT directly depends on interoperability between IIoT platforms. Today, we are dealing with various vertically oriented and mostly closed systems. Architectures for IIoT are built on heterogeneous standards or even proprietary interfaces. This causes interoperability problems when the overarching, cross - IoT platform and cross-domain applications are to be made. It also leads to barriers for small innovative businesses, which cannot afford to offer their solution across multiple IoT platforms.

Most of today's businesses look for adaptability, flexibility, and ease of implementation for their IT setup. But at the same time, enterprises need maximum reliability, security, and predictability for their IIoT landscapes. Meeting these needs requires a new architecture. To address these shortcomings in today's IIoT landscape, experienced developers turn to the BIG Industrial IoT architecture as an enabler for establishing IIoT infrastructures. It overcomes the “classic IIoT architecture" shortcomings through a standard Web API and semantic descriptions of resources and services. Implementing such architecture as part of the BIG IIoT project allows new applications to be created by combining data from multiple. Also, IoT platforms from various domains can be combined so that applications can utilize all relevant information and work seamlessly across regions.

Instead of a conclusion

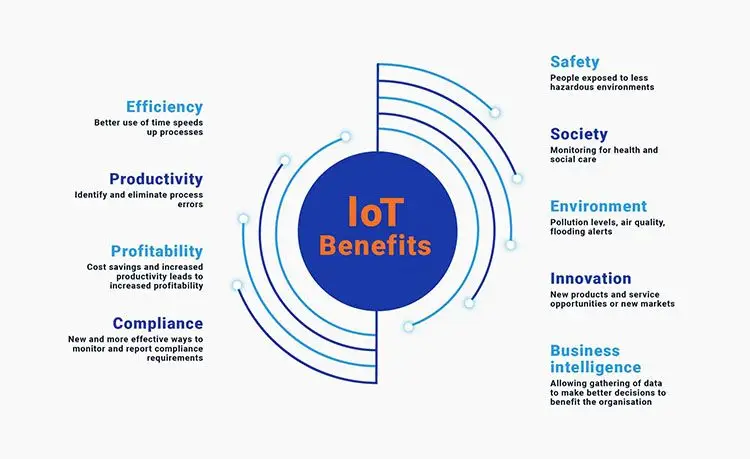

IIoT technologies are very beneficial for business: it is easier to prevent breakdowns than to spend money on repairs and replace manual labor with automated ones. The Industrial Internet of Things for business brings enormous benefits:

- Increases profitability: revenues increase and costs decrease;

- Optimizes business processes;

- Improves the buyer's user experience and increases engagement;

- It makes production safe for employees and the environment;

- Increases customer orientation.

The mass adoption of IoT in business is a slow but irreversible process that will accelerate to a certain extent with the development of technology. So let's tackle the industries IoT improves:

- Logistics: Tracking routes and laying paths, monitoring the state of transport, calculating profitable ways and times of cargo delivery — all this is under the power of the Internet of Things. After all, this technology began precisely with the optimization of logistics.

- Production: Sensors in factories or agricultural farms monitor the condition of equipment, crops, livestock, and soil, and the platform monitors processes with minimal human involvement. Process automation means speeding up, optimizing costs, and increasing profits.

- Storage of goods: Sensors and "smart" devices automatically monitor the state of warehouses: storage conditions, occupancy level, and more. Proper storage reduces the number of spoiled goods and waste and, accordingly, losses.

- Marketing: If marketing is positioned as the philosophy of the product and its evaluation from the point of view of the customer's user experience, then the Internet of Things provides invaluable benefits. This is the collection and analysis of data about the audience, its behavioral habits, and preferences to create a portrait of the buyer and determine the criteria for the probability of selling a specific product at the right time.

- Retail: Points of sale can quickly communicate with warehouses and deliver the necessary goods, transmit data about the demand for products and make requests.

Looking for experienced IIoT developers to deliver your innovative solution? Contact our IoT team today!

Browse our case studies and get actionable insights to drive your success

See more