- AI/ML & Computer Vision Engineering

- MVP Development

- Architecture & Infrastructure Design

- Data Engineering & ETL

- Hardware & Conveyor Integration (cameras, PLC/API)

- Web App & Dashboard Development

- REST API Integration

- QA & Test Automation

- DevOps & CI/CD

- Security & Compliance

- Pilot Rollout & Support

AI parcel damage detection

Computer-vision QC that flags damaged parcels in real time

A production-grade computer-vision system that identifies physical damage and moisture/wetness on parcels moving at conveyor speed. Trained on thousands of annotated examples, deep-learning models analyze live multi-angle camera feeds, classify issues in real time, and automatically flag items for secondary inspection or escalation. An operations dashboard gives teams live monitoring, clear damage/moisture labels with evidence frames, and searchable audit trails.

Industry

AI

Headquarters

USA

USA

Services we provided

About the Client

A national parcel delivery service operating multiple warehouses and sortation hubs. Quality checks were manual and inconsistent, slowing throughput and allowing damaged packages to slip through to downstream nodes and customers. The client sought an automated, objective visual inspection that would scale with conveyor speed and reduce human error.

Challenge

Manual visual QC could not reliably catch subtle tears, dents, or early signs of wetness, and accuracy varied by shift. High conveyor speeds left too little time for dependable inspection, forcing lines to slow or accept higher risk. Labels were inconsistent, and there was no standardized taxonomy or audit trail, limiting the audit to damage and moisture classes, which made performance difficult to compare across sites. Even when defects were spotted, flagged parcels often lacked a consistent escalation path (e.g., re-pack/dry, return-to-sender, or claim), leading to rework and uneven outcomes. The client required a scalable vision system dedicated to damage/moisture detection that would automatically flag parcels, route them to secondary inspection, and provide measurable, auditable results.

Solution

-

Real-time image ingestion

High-speed cameras capture parcels from multiple angles as they move along the conveyor. Frames are synchronized to parcel IDs, allowing detections to be actioned downstream.

-

Deep learning classification

Models trained on labeled datasets can distinguish between damaged and intact surfaces and detect moisture/wetness (such as water stains, dark patches, or gloss/reflectivity cues). Confidence scores and heatmaps highlight the exact region of concern.

-

Automated flagging & routing

Parcels that cross configurable confidence thresholds are automatically flagged and diverted to a secondary inspection lane, without slowing the central belt.

-

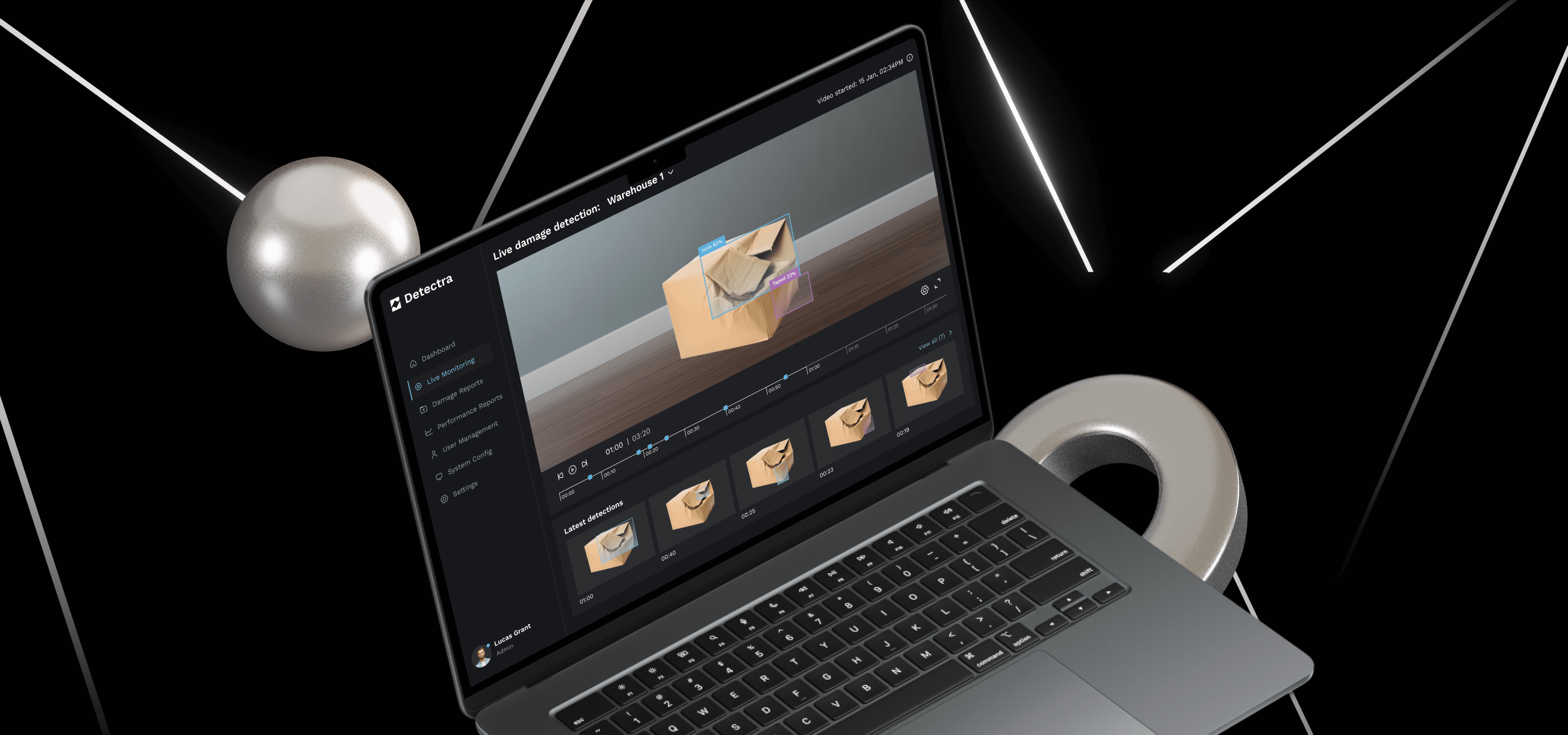

Operational dashboard

A central web app shows live detections, damage/moisture labels, reviewer queues, and station performance. Supervisors can drill into frames, see heatmaps, and confirm/override results.

-

Warehouse integration

API/PLC hooks synchronize events with conveyor controls (gates/diverters) and, where necessary, with WMS/TMS, ensuring that flagged items follow the correct handling path.

-

Audit & feedback loop

Reviewer confirmations feed back into the training set to continuously improve precision/recall for both damage and moisture classes.

Features Delivered

-

Real-time image processing

Low-latency inference on live camera streams to keep pace with conveyor speed.

-

Model trained on damage datasets

Robust performance from thousands of annotated examples and continuous retraining.

-

Conveyor system integration

Hardware and control-system hooks for gates/diverters and station alerts.

-

Camera feed integration

Multi-angle capture for higher detection confidence on irregular parcels.

-

Dashboard with alerts & logs

Live detections, category/class labels, user queues, and searchable history.

-

Automated flagging

Confidence-based triggers to pull parcels for review without manual intervention.

-

Automated escalation

Configurable workflows for QC review, re-pack, return-to-sender, or claim processes.

Key results and business value

-

4× lower cost of detection

Automation reduced labor per inspected parcel and improved line utilization versus manual spot checks.

-

+85% accuracy

Data-driven detection outperformed manual checks and cut false passes, especially for subtle wetness on kraft packaging.

-

40% less inspection time

Auto-flagging and routing compressed end-to-end QC time without reducing throughput.

-

Higher customer satisfaction

Earlier interception of damaged or wet parcels prevented downstream failures and improved customer experience.

-

Operational visibility

Standardized labels and logs enabled root-cause analysis by site/shift/vendor and informed packaging/process fixes.

-

Scalable quality program

Architecture and workflows are replicated across warehouses with minimal adjustment, while the feedback loop keeps damage/moisture models improving over time.