IoT

How Live Parcel Updates with IoT Enables Damage‑Free Deliveries

Introduction

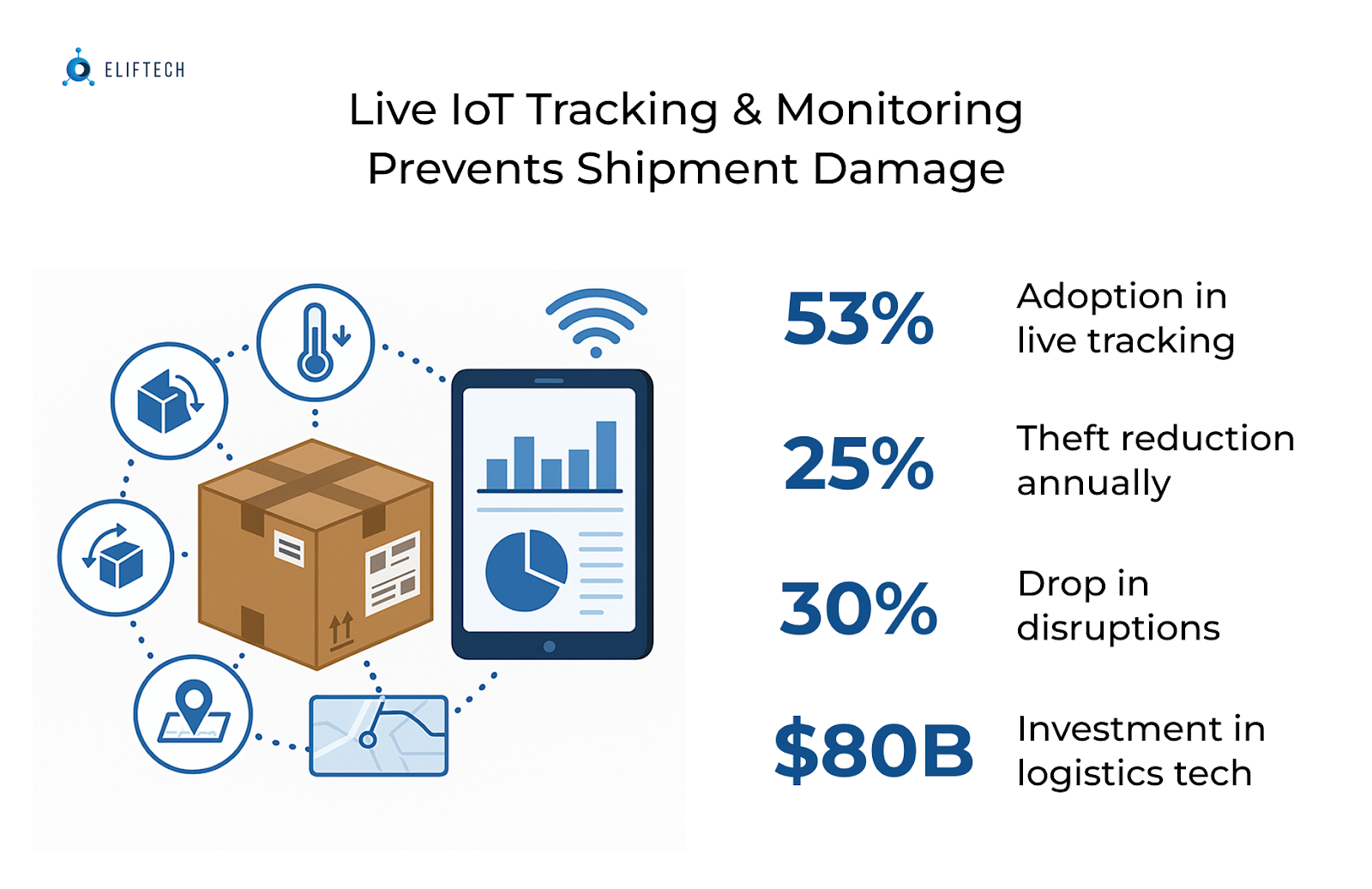

Today, last-mile delivery accounts for almost 41% of all logistics costs, placing significant pressure on companies to prevent issues such as damaged goods, theft, or lost packages. The old method of barcode scanning only shows a package’s location at one single moment, leaving long gaps with no visibility.

At the same time, customers and carriers expect real-time updates throughout the entire journey. That’s why tracking live parcels with IoT is a must-have. It helps close those gaps, lowers costs, improves accountability, and keeps a company’s reputation safe by ensuring shipments will be tracked every step of the way.

Smarter monitoring with IoT sensors

Traditional barcode scans only tell you that a package was moving at a certain point in time. They don’t capture what really happens during the trip, such as shocks, tilts, sudden temperature changes, or humidity levels. By contrast, IoT smart tags with sensors (RFID, GPS, accelerometers, environmental trackers) provide continuous, detailed monitoring and create a digital twin of every parcel in motion.

Companies that started using shock and tilt sensors saw a 40% drop in damage-related incidents within just six months. This proves that when you can see what’s happening in real time, you can control it.

IoT data can also flag risks such as spoiled refrigerated goods or stolen shipments. A recent Tive analysis showed that real-time shock, tilt, and light exposure data sharply improved fraud detection for tampered loads. With global spending on IoT in logistics expected to hit $139 billion in 2025 (up from $114.7 billion in 2024), it’s clear that investment is moving from random spot-checks to fully connected supply chains.

Live telematics let operators map out risk zones such as high-vibration routes or unstable stacking areas. And with digital twins powered by sensor data, control towers can simulate stress points and reroute shipments before damage occurs.

Real-Time Alerts Prevent Loss

Real‑time IoT alerts transform reactive supply chain operations into proactive, risk‑mitigated workflows enabled by digital twins.

Unlike older systems that can only collect data, IoT solutions provide instant, actionable responses. For example:

- With geofencing, managers get an immediate alert if a delivery vehicle goes off its planned route.

- Vibration and shock sensors send alerts when a package is dropped or shaken, protecting fragile items such as electronics.

- For temperature-sensitive cargo, cold chain tags trigger when safe limits are exceeded, giving refrigerated trailers time to adjust or reroute before goods spoil.

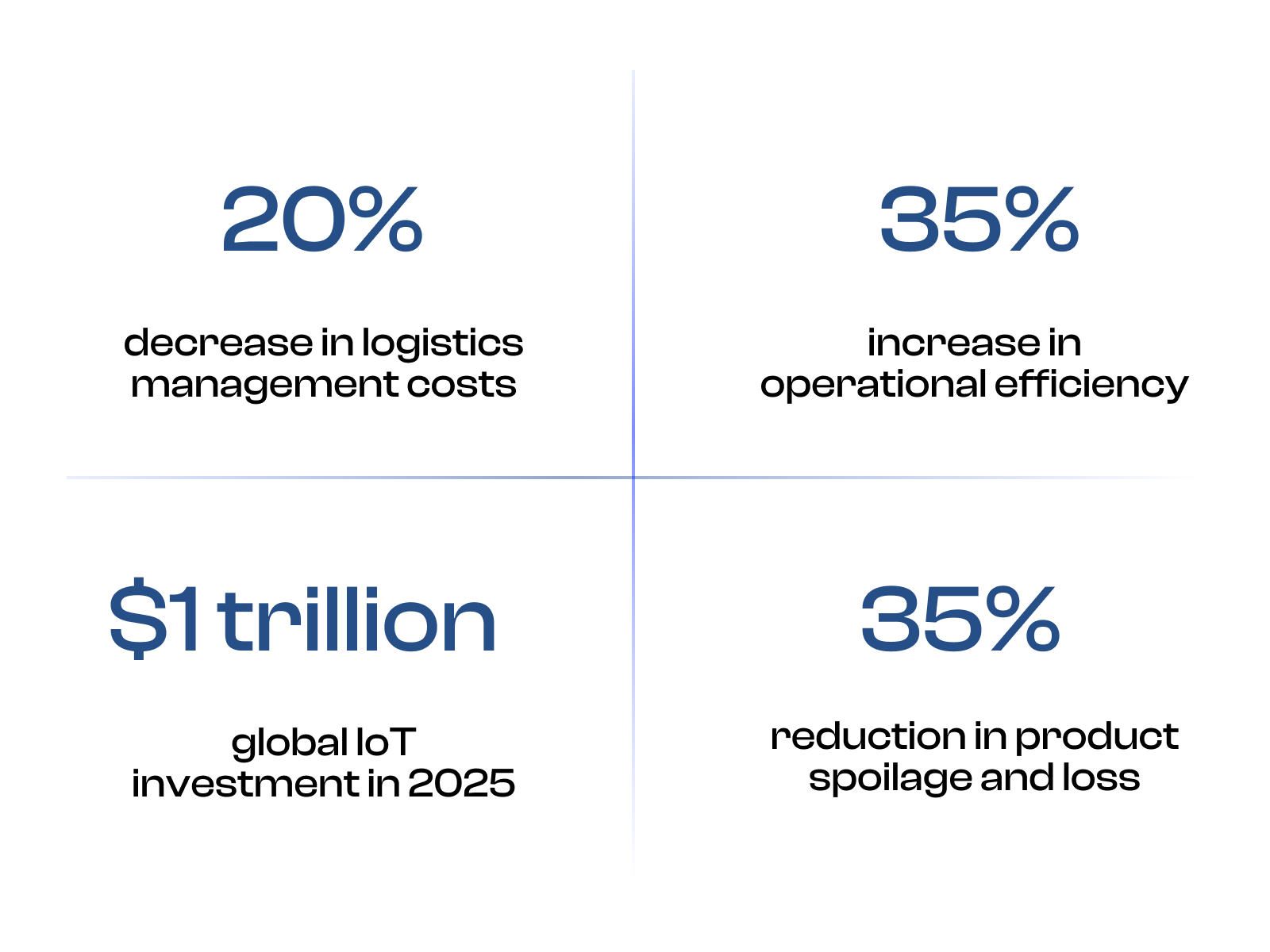

Сompanies that implement real-time IoT alerts have seen logistics management costs drop by 20 % and operational efficiency increase by 35%, thanks to reduced exceptions and automatic interventions. IoT Analytics projects global IoT investment to reach $1 trillion in 2025, with logistics among the fastest-growing verticals.

McKinsey & Company also reported that companies integrating IoT alerts into cold-chain and high-value shipments cut spoilage and losses by 30–50%, especially in pharmaceuticals and perishables. Real-time monitoring has also reduced delivery exceptions by up to 70%, which translates into a 15% boost in SLA compliance and a 40% increase in B2B customer retention.

When IoT sensor data is combined with AI-based alert systems, logistics becomes a data-driven network where decisions are made based on current events rather than scheduled checks.

By the end of 2025, over 65% of logistics organizations are expected to use predictive alerting powered by IoT and AI. This will allow them to optimize routes dynamically, manage cold chains in real time, adjust delivery windows, reduce claims, and increase productivity per asset.

Better handling through accountability

Real-time IoT tracking in warehouses and transport has completely changed how logistics teams ensure compliance with processing standards. Now every parcel movement can be timestamped, with data on impacts, tilts, and temperature changes recorded along the way. This gives operators clear visibility into how goods are treated at every transfer point. A 2024 meta-analysis found that facilities using sensor-based tracking cut losses of handling-related products by 15–25%.

Accountability no longer depends on manual supervision or after-the-fact audits. Instead, logistics control centers receive a continuous stream of data that flags anomalies in real time, allowing teams to step in immediately. The benefits extend beyond damage prevention: in highly regulated industries such as pharmaceuticals or luxury retail, IoT-enabled traceability also supports compliance, audit readiness, and verified chain-of-custody.

For instance, before real-time monitoring, the movement of high-value goods, particularly in luxury fashion, had serious visibility gaps. Barcode scans and tamper seals offered little protection against unauthorized access, temperature swings, or rough handling. Problems often went unnoticed until delivery, leading to reactive investigations, rising claims, and reputational damage.

To address this, a European logistics provider running premium fashion shipments launched a pilot program in 2023. Each parcel carried RFID tags for custody verification, accelerometers for impact detection, and environmental sensors for temperature, humidity, and light monitoring. All sensor data was securely stored on the blockchain, creating an immutable, verifiable chain of custody that ensured product integrity and transparency of operations from start to finish.

The results were impressive. During the pilot project, no cases of fraud were recorded, as real-time notifications and auditable data provided complete protection. Customer complaints decreased by 20% thanks to transparent monitoring and full traceability. At the same time, customer satisfaction increased as shippers received certified integrity reports, which strengthened trust and encouraged repeat orders.

The case highlights how integrating IoT telemetry with blockchain creates a robust “digital envelope” around each asset, one that is both sensor-protected and cryptographically secure. For logistics operators, that means fewer exceptions, faster claims resolution, stronger SLAs, and, most importantly, reliability in industries where product integrity is non-negotiable.

Business impact

Delivering goods without damage creates measurable improvements across operations, finance, and customer trust. Since last-mile shipping can account for around 41% of total logistics costs, every damaged package carries multiple consequences: a claim, wasted freight, extra labor for manual inspections, and even potential SLA penalties when carriers are held responsible. Using IoT parcel tracking delivers high returns: companies reported a 42% reduction in damage claims and a 25% increase in delivery satisfaction within six months, as well as significant decreases in exception handling and quality control costs.

Some freight forwarders have gone a step further, turning these improvements into new revenue streams. Moeco found that businesses offering IoT-powered visibility achieved a 30% increase in revenue per shipment, supported by premium tracking services and fewer post-delivery disputes. In cold chain logistics, product spoilage has decreased by 25–35%, and SLA compliance has increased by 15% thanks to real-time sensor data confirming process compliance.

The broad market supports this change. Global spending on IoT logistics solutions continues to rise, with 92% of enterprises reporting positive ROI in 2024. By 2025, annual investment is expected to exceed US$61 billion, driving the adoption of digital control towers, predictive analytics, and exception-based workflows across the industry.

For shippers and 3PLs managing high-volume SKUs, from perishables to high-value electronics, the outcome is clear: fewer claims, faster resolution cycles, lower inspection overhead, and higher customer retention. Parcel-level visibility is now the basis for operational excellence and commercial differentiation, shifting the cost-per-delivery model from reactive expense to strategic investment in reliability, efficiency, and service excellence.

Implementation tips

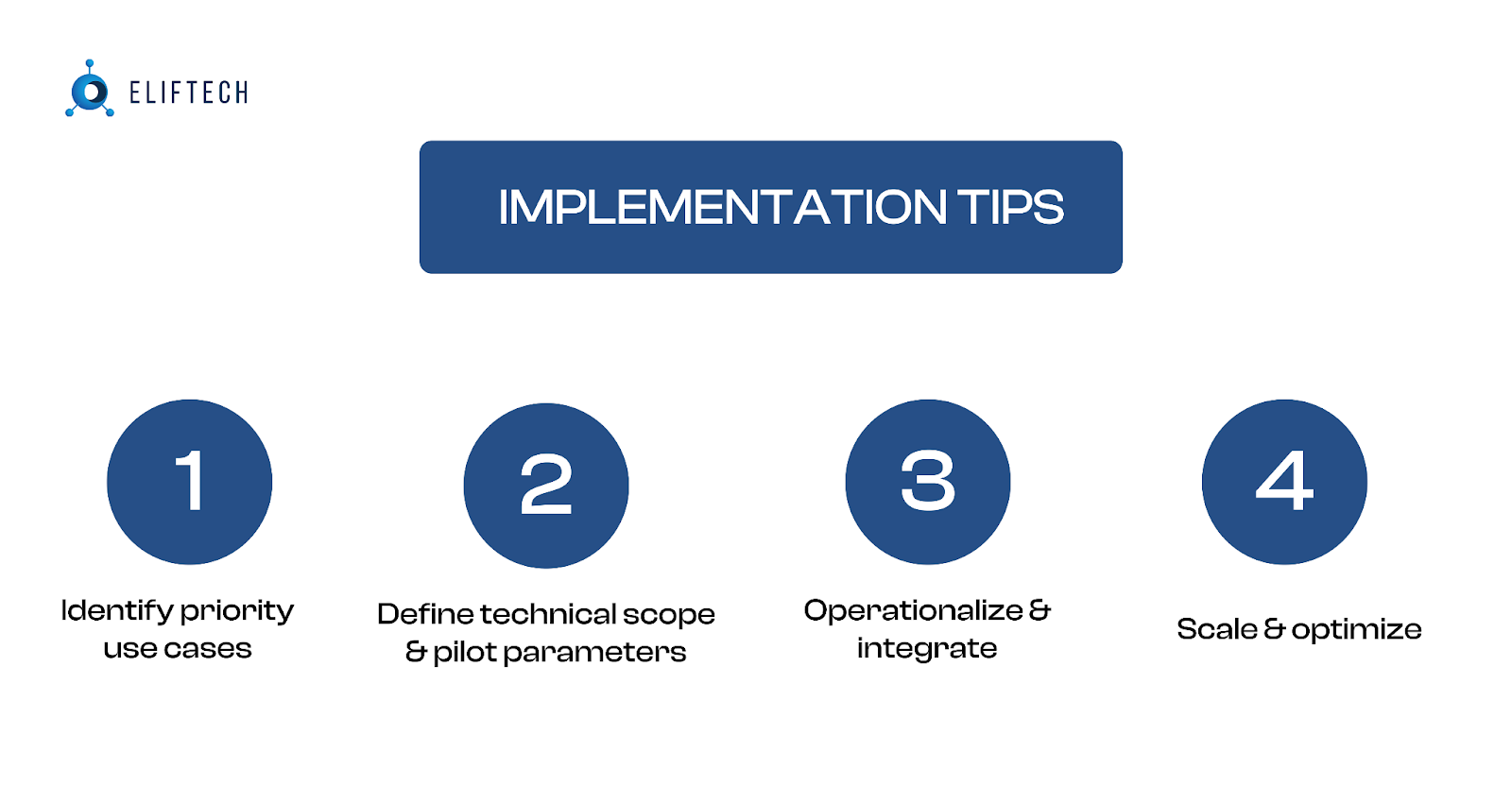

1. Identify priority use cases

Start by mapping out the high-risk categories, for example, temperature-sensitive goods, high-value electronics, or fragile items. Then look at historical claims data to spot specific routes, handoff points, or facilities where exceptions happen more often. Finally, bring together teams from Operations, Quality, Claims, and Customer Service to align on success metrics and build a single, coordinated plan to reduce those risks.

2. Define technical scope & pilot parameters

Start by choosing a small control group, for example, one or two high-priority lanes or a key customer account, to act as your proof of concept. Select sensors that match the cargo’s specific risk profile, such as shock or tilt detection, ambient temperature tracking, humidity monitoring, parcel integrity checks, or geofencing. Make sure the IoT devices fit smoothly into your current packaging and shipping processes, with a focus on mountable, tamper-resistant, and reusable designs. Verify that the devices work with your existing TMS, WMS, or integration middleware so data flows in seamlessly. Lastly, set up clear notification rules, including threshold-based alerts, escalation steps, and direct routing to your control tower or operations team for immediate action.

3. Operationalize & integrate

Create clear standard operating procedures for device provisioning, activation, and return, especially important when working with reusable IoT tags. Integrate alert workflows directly into dispatch and claims processes to handle exceptions in real time and resolve them faster. Build a centralized reporting dashboard to monitor lane-level performance, asset traceability, and carrier SLA compliance. Provide warehouse teams and drivers with hands-on training on how to apply, handle, and maintain the devices. Finally, set up a closed-loop feedback system with your analytics team to continuously measure ROI and adjust deployment settings based on actual performance data.

4. Scale & optimize

Scale the program by expanding sensor coverage to more freight lanes, high-risk SKUs, or even entire business units, using the lessons learned and ROI from the pilot as your foundation. Work closely with 3PLs, carriers, and insurers to create clear data-sharing agreements that ensure transparency and shared responsibility across the logistics network. Use sensor data not just for monitoring, but to guide strategic improvements in route planning, packaging strength, and load configuration. Move from reactive alerts to predictive analytics and anomaly detection, enabling teams to address potential issues before they occur. Keep device firmware up to date, refine data models, and adjust performance thresholds regularly to match evolving risks and shipment profiles.

Final thoughts

The ability to track the status of parcels in real time is a key operational requirement. IoT-enabled shipment visibility equips logistics providers with the tools to reduce claims, improve SLA performance, and optimize exception management at scale.

With tools like lane-specific risk profiling and proactive, condition-based routing, companies can move away from reactive workflows and instead rely on smart, data-driven decisions. Equally important, IoT systems create verifiable supply chain records, ensuring full accountability at every stage, from origin to final delivery.

For 3PLs, shippers, and freight forwarders, investing in IoT infrastructure is crucial, as it directly protects margins, improves customer loyalty, and increases efficiency across the entire network. Those who build sensor-driven intelligence into their logistics operations will set the standard for service quality, resilience, and trust in the next era of supply chain performance.