Logistics

How Transportation Leaders Can Save $1.5M Annually

Introduction

By strategically integrating Transportation Management Systems (TMS), Warehouse Management Systems (WMS), and Enterprise Resource Planning (ERP), transportation leaders can unlock significant cost savings. These systems each target different facets of logistics, and when working in unison, they create end-to-end efficiency. Companies have reported double-digit percentage reductions in freight costs, fuel usage, and operational errors by deploying these technologies. The cumulative effect makes an annual savings goal of $1.5 million realistic for mid-sized logistics operations. In this article, we’ll explore how integrating TMS, WMS, and ERP streamlines processes, reduces waste, and drives powerful savings. We’ll cover what each system does, its individual benefits, the combination of full integration, a breakdown of the $1.5M target, an implementation roadmap, real-world results, and how to overcome integration challenges.

Understanding the Systems

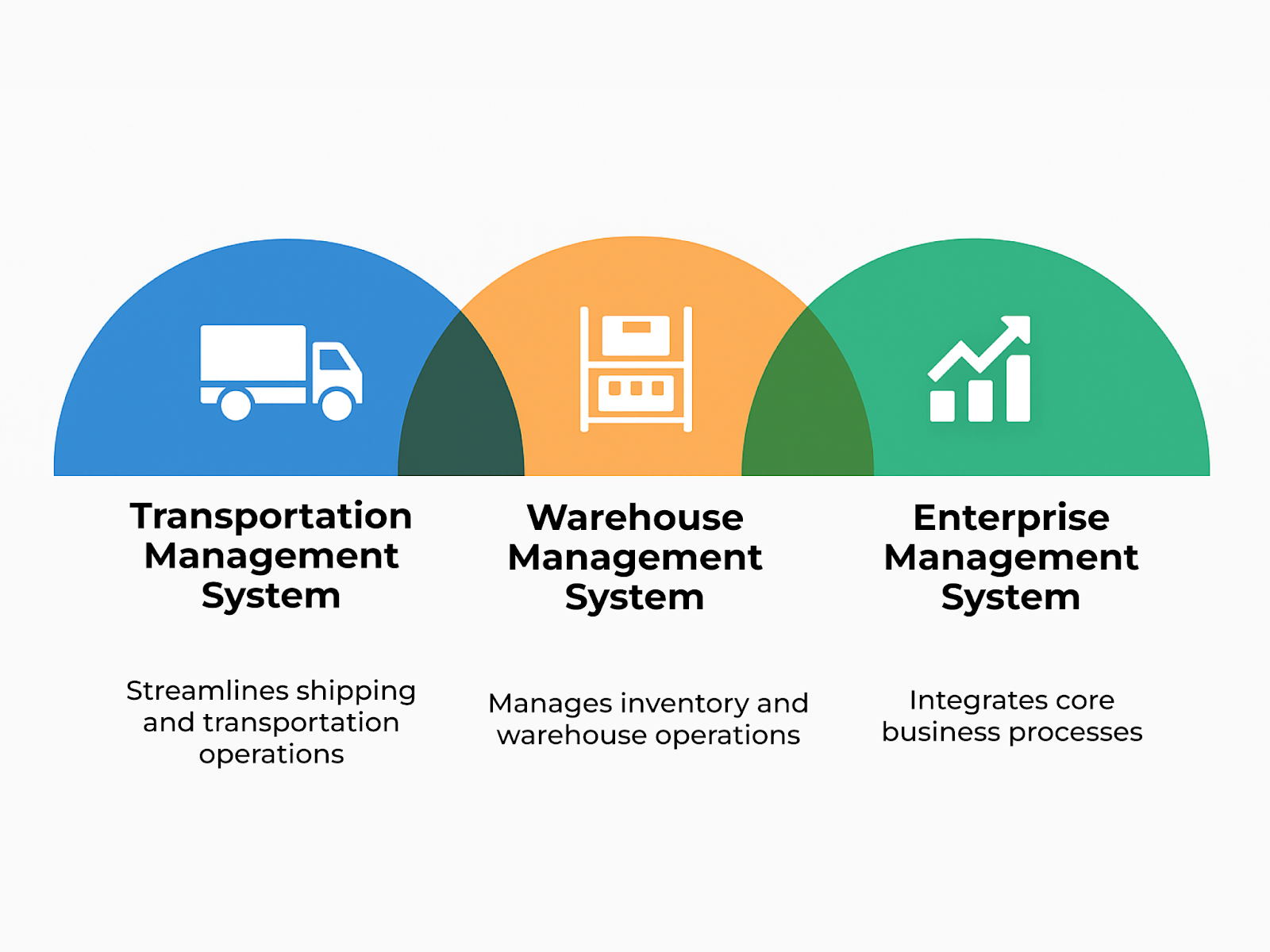

Transportation Management System

A Transportation Management System (TMS) is software that simplifies shipping and transportation operations from planning shipments and optimizing routes to tendering loads and auditing freight bills. It provides functionalities like load planning, carrier selection, route optimization, shipment tracking, and freight payment management. In essence, a TMS handles everything once an order is ready to ship: it finds the best way to move goods to customers efficiently. By automating dispatch and routing, a TMS helps companies minimize empty miles, avoid delays, and ensure compliance with shipping requirements. It provides real-time visibility into shipment locations and helps manage transportation costs. The TMS picks up where the warehouse leaves off, coordinating the “last mile” delivery and carrier logistics.

Warehouse Management System

A Warehouse Management System (WMS) is focused on managing inventory and warehouse operations inside distribution centers. It tracks product inventory levels, locations, and statuses in real time. Core functions include guiding efficient picking and packing of orders, managing inbound put-away and outbound shipping, and optimizing warehouse space and labor. A WMS acts as the control center for all activities inside the warehouse, ensuring that orders are fulfilled accurately and inventory is stored and replenished optimally. By using barcode scans or automation, a WMS reduces manual errors in inventory counts and speeds up order fulfillment. This leads to faster shipping cycles and better use of warehouse resources. In short, the WMS keeps warehouse inventory under control and orders flowing out without delay.

Enterprise Resource Planning

An Enterprise Resource Planning (ERP) system serves as the company’s operational and financial nerve center. It is an integrated platform that handles core business processes across departments, including procurement, order management, inventory, finance/accounting, HR, and more. In the context of logistics, the ERP records customer orders, initiates purchase orders for supplies, and tracks financial metrics like cost of goods and billing. Think of the ERP as the master system where all transactional data converges. It ensures all departments work from the same data, so the sales team knows current inventory, finance knows the latest shipping costs, and management can see overall operational performance. The ERP provides the unified data backbone that other systems (like WMS and TMS) plug into. By itself, an ERP provides enterprise-wide visibility and standardizes processes, but it may lack specialized logistics functionality; that’s where integrating it with WMS and TMS becomes powerful.

Individual Benefits of Each System

Synergistic Power: Integrating TMS, WMS, and ERP

Integrating these three systems: ERP, WMS, and TMS, unleashes synergistic benefits greater than the sum of their parts. Each integration pairing addresses a gap, and together they create a fully unified logistics ecosystem:

ERP ↔ TMS Integration

Connecting the ERP and TMS establishes a seamless flow of order and shipment information across procurement, finance, and transportation. This eliminates manual data re-entry (for example, orders automatically flow from ERP to TMS), ensuring accuracy and real-time visibility into shipments. Procurement and finance teams can see freight costs and shipment statuses directly in the ERP, while the TMS gets up-to-date order details and inventory availability. The integration minimizes errors and delays caused by mismatched data. It also enables better cost control; transportation decisions are made with full knowledge of orders, inventory, and budgets from the ERP, leading to more cost-effective shipping choices. An ERP–TMS link essentially aligns transportation execution with the company’s broader business objectives and financial plans. The result is improved shipment visibility for all stakeholders and tighter control over transportation spend and billing.

TMS ↔ WMS Integration

Integrating the warehouse management system with the TMS links warehouse operations directly with transportation planning. When these systems work together, order fulfillment and shipping are coordinated in real time. For instance, as soon as an order is picked and packed in the WMS, that data flows to the TMS to plan the outbound shipment, with no manual handoffs. This integration eliminates duplicate data entry (warehouse staff don’t have to re-key load info into the TMS) and ensures that both systems are always in sync regarding what’s shipping. Companies gain end-to-end visibility into each load’s status without switching between systems, e.g., a manager can see that an order has left the warehouse and is en route, all in one interface. A TMS–WMS integration also improves scheduling and resource utilization. With the TMS aware of warehouse activities, trucks and drivers can be scheduled more precisely (e.g., dispatch arrives when an order is ready), and warehouse labor can be aligned to outbound loading needs. This reduces dwell times and avoids duplication of effort. Overall, linking TMS and WMS yields faster, more accurate shipments and real-time updates.

ERP ↔ WMS Integration

Integrating the ERP and WMS ensures that inventory data and order information flow seamlessly between enterprise planning and warehouse execution. The ERP’s purchase and sales orders synchronize with the WMS’s receiving and shipping transactions in real time. This gives a unified, accurate view of inventory across the organization; the quantity on the warehouse shelf always matches the ERP’s records. Such consistency enables better inventory optimization and resource utilization. Planners can use ERP analytics together with WMS data to optimize stock levels at each location, avoiding overstock (which ties up capital and space) and stockouts (which cause lost sales). By analyzing demand patterns, an integrated system can trigger timely replenishment and adjust safety stock, reducing holding costs while ensuring customer demand is met. Integration also speeds up responses to demand changes – for example, a surge in orders in the ERP will immediately cue the WMS to allocate inventory and labor so that the warehouse can scale up output without chaos. Overall, ERP–WMS integration leads to tangible cost reductions through more efficient inventory management and the elimination of duplicate efforts.

Full Tri-System Integration (ERP + WMS + TMS)

When TMS, WMS, and ERP are fully integrated, supply chain data flows seamlessly, orders, inventory, and shipments are all connected. This eliminates silos, reduces errors, and gives leaders real-time visibility from procurement to delivery. A delay in the warehouse can instantly update transport schedules and finance, ensuring fast, data-driven responses. Full integration also unlocks advanced analytics, minimizes duplicate work, and keeps all departments aligned. The result is a more agile, proactive logistics network that delivers fewer surprises, faster resolutions, and sustained multimillion-dollar savings.

Quantifying the $1.5M Annual Savings Target

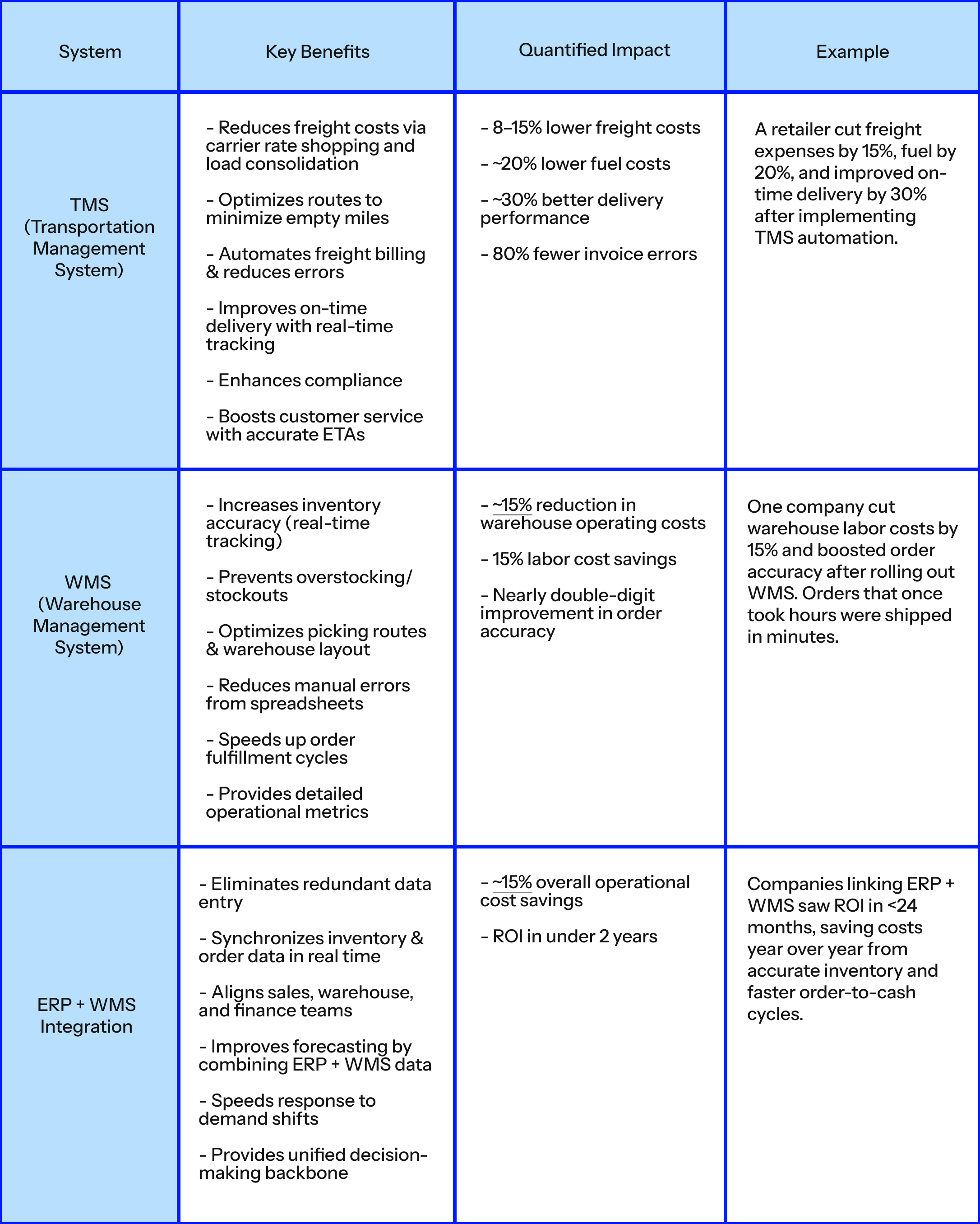

1. By implementing a TMS, companies typically save around 10–15% of freight costs via better routing and carrier management. If our example company spends $5M per year on freight, a 15% reduction is $~$750,000$ saved. Additionally, fuel expenses drop by up to 20% with optimized routes; if fuel is a significant portion of costs, that could be another few hundred thousand dollars. Beyond direct cost cuts, TMS automation often eliminates billing overpayments and late delivery penalties. With 80% fewer invoice errors, the company would save money that previously leaked out due to billing mistakes or carrier discrepancies. These transportation efficiencies easily contribute $500k–$800k in savings.

2. A WMS can reduce warehouse operating expenses by roughly 15% through improved efficiency and accuracy. If the company’s warehousing and fulfillment costs are $5M annually (labor, carrying costs, etc.), the WMS would save around $~$750,000$ by cutting wasted labor, avoiding stock losses, and optimizing space utilization. For instance, fewer picking errors means far fewer costly returns or re-shipments. Better inventory management means the company isn’t paying to store excess stock or emergency shipping for stockouts. Many firms see an order of 15% productivity gains and cost reduction in their distribution centers from WMS adoption. In dollars, that’s easily another $500k–$800k saved per year.

3. Integrating the ERP with these systems adds an extra layer of savings by eliminating manual processes and errors between departments. For example, automatic data flow prevents revenue leakage from missed billing or incorrect charges. If billing errors or inventory mistakes previously cost even a few percentage points of revenue, the integration might save on the order of $100k+ by tightening financial controls. Real-time data also improves financial decisions, e.g., avoiding costly emergency shipments thanks to better planning. While harder to quantify, these savings (in reduced errors, better procurement decisions, etc.) might contribute another $100k–$200k annually. The integration also enables consolidated shipments and optimized planning that further scale up savings. By having all systems linked, the company can, for instance, combine orders into fuller truckloads (leveraging TMS suggestions) and plan production or ordering to minimize logistics costs. This holistic optimization could easily push the total savings closer to the $1.5M goal.

Integrating ERP with TMS and WMS eliminates manual errors, prevents revenue loss, and strengthens financial control, often saving between $100,000 and $200,000 per year. Real-time data enables better planning, consolidation of shipments, and fuller truck loads, bringing total savings closer to the $1.5 million target.

Implementation Strategy

1. Establish baselines. Audit current operations and costs (freight, fuel, warehouse labor, order accuracy, on-time delivery, invoice errors). These KPIs will highlight inefficiencies and provide benchmarks for measuring progress. Engage stakeholders across departments to identify and address pain points.

2. Define objectives & savings targets. Set clear goals aligned to the $1.5M target, e.g., cut transport cost per load by 15%, boost warehouse throughput 20%, or reduce manual errors 80%. Concrete, measurable objectives keep the project focused and secure leadership buy-in.

3. Choose the right systems. Select TMS, WMS, and ERP platforms with proven integration capabilities, APIs, or pre-built connectors. Look for scalable, analytics-driven solutions that can grow with your business. Involve both IT and operations leaders in the decision.

4. Phase the rollout. Reduce risk by starting small. Begin with ERP–WMS alignment to stabilize inventory accuracy, then layer in TMS for transport optimization. Pilot test on a limited scope to refine workflows before full deployment, prioritizing high-impact integrations first.

5. Training & change management. Success depends on adoption. Provide thorough training for all teams, explaining how integration makes their work easier. Appoint “champions” in each department to support peers and build buy-in across the company.

6. Monitor & continuously improve. Track KPIs with dashboards and regular reviews. Use data to fix bottlenecks, adjust processes, and fine-tune carrier and inventory strategies. Treat integration as an ongoing improvement program, not a one-time project, to sustain and grow savings.

Challenges & Mitigation

While the benefits of integrating TMS, WMS, and ERP are compelling, it’s important to acknowledge the challenges that may arise and plan mitigation strategies. Implementing multiple interconnected systems is not without difficulties:

Common Challenges:

1. Integration complexity. Configuring different systems to talk to each other can be complex. Each system might have its own data formats and business rules. System compatibility issues or mismatched data fields are common hurdles. For example, ensuring the ERP’s “customer ID” field matches the WMS’s “client number” requires careful mapping. Customizing integrations or using middleware can add cost and time.

2. Data quality issues: “Garbage in, garbage out” applies; if your existing data (inventory records, product codes, etc.) is inaccurate or inconsistent, integrating systems will simply propagate those errors. Poor data quality can lead to incorrect decisions by the new system or integration failures. Without cleansing data, a WMS might, for instance, be loaded with wrong inventory counts from the ERP, undermining its value.

3. Change management & user adoption. These new systems will alter long-established processes. Employees might resist changes to their routines or distrust the new software initially. Getting teams to fully adopt the TMS or WMS (instead of reverting to spreadsheets or old methods) can be a challenge, especially if training is insufficient. There’s also a learning curve; productivity can dip during the transition period if users struggle with the new interfaces.

4. Upfront costs and training. There are upfront investments in software licenses, integration services, and possibly new hardware. Additionally, significant training costs and time need to be allocated. During training and early use, normal operations might slow down, which can be painful for a busy logistics team. Management might worry about the short-term disruption or costs before the ROI kicks in.

5. Ongoing maintenance. Integrated systems require maintenance, software updates, API management, and data flow monitoring, which may strain a small IT team. Any change (like an ERP upgrade or a new carrier API for the TMS) can necessitate adjustments in the integration. Companies need to be prepared for continuous IT involvement or vendor support, which can be challenging if resources are limited.

Mitigation Tactics:

Despite these challenges, there are proven ways to mitigate risks and ensure a smooth integration journey:

1. Thorough planning and phased approach. Plan the integration project in detail before diving in. This includes a data audit and cleanup before migrating anything, fixing inconsistent product codes, purging outdated records, and standardizing data formats across systems. A well-defined project plan with phases (as described in the implementation strategy) will isolate complexity and allow learning. Start with simpler integrations or a pilot site to work out kinks on a small scale. This approach prevents a “big bang” failure and builds confidence step by step.

2. Use integration tools and experts. Use modern integration middleware or no-code/low-code platforms with pre-built connectors to reduce custom coding. Many integration platforms can map data between ERP, WMS, and TMS with drag-and-drop tools. This not only speeds up the project but also abstracts away a lot of technical complexity. If the budget allows, bring in integration specialists or consultants who have done similar projects; their expertise can preempt many issues. Essentially, don’t reinvent the wheel if a connector for your ERP and chosen TMS already exists. Using APIs and standard protocols also makes the system more future-proof.

3. Invest in training and change management. As mentioned, get users involved early. Conduct workshops demonstrating how the integrated systems will work and how they benefit each role (for example, show customer service reps how they’ll be able to answer “Where’s my order?” instantly in the new system). Develop comprehensive training materials and possibly a sandbox environment where users can practice. Executive sponsorship and communication are key; leadership should frequently communicate the importance of the project and support employees through the change. Recognize and reward teams for adapting, and provide ample support (like a helpdesk or “super user” on the floor) during the go-live period.

4. Pilot and iterate. Use a pilot implementation to test integration flows in real conditions. This can be a single warehouse or one business unit. Monitor the pilot closely and gather feedback from users. Encourage them to identify pain points or any confusing steps. Then refine the processes and system configurations before broader rollout. This iterative approach catches issues when they are easier (and cheaper) to fix, minimizing disruption later.

5. Allocate sufficient resources. Make sure you budget not just for software, but for the integration work and ongoing maintenance. It might mean having an IT point person dedicated to the project or contracting support from the vendors. Also, plan for the temporary workload increase during implementation, hire temporary staff, or reduce other initiatives so your team can focus on this. The goal is to avoid burnout and ensure the project gets the attention it needs. Post-implementation, consider appointing a system owner or admin for each of TMS and WMS who monitors performance, updates, and user feedback. With someone accountable, minor issues can be addressed before they become big problems.

Conclusion

Integrating TMS, WMS, and ERP is a necessity. On their own, each system improves efficiency, but together they unlock real-time visibility, fewer errors, and savings of up to $1.5M annually. The benefits go beyond cost: faster deliveries, better customer service, and more agile decision-making.

Companies that integrate these tools report double-digit performance gains and quick ROI, turning logistics from a cost burden into a competitive advantage.

So audit your systems, identify gaps, and build a roadmap toward integration. With leadership buy-in and a phased rollout, you can minimize disruption and maximize impact.

It’s time to move beyond isolated systems. Integration delivers sustained savings, resilience, and growth, and positions your business to thrive in the future of logistics.