AI

Safeguard Your Shipments with AI-Powered Parcel Damage Detection

Introduction

Damaged parcels are a big problem for logistics and e-commerce businesses. Up to 11% of shipments arriving at distribution centers suffer some form of damage. Handling these incidents, from replacing products to managing customer complaints, quietly chips away at efficiency and revenue. In fact, in-transit damage is estimated to cost companies about 0.5% of gross sales (roughly $1 billion in losses annually in the USA).

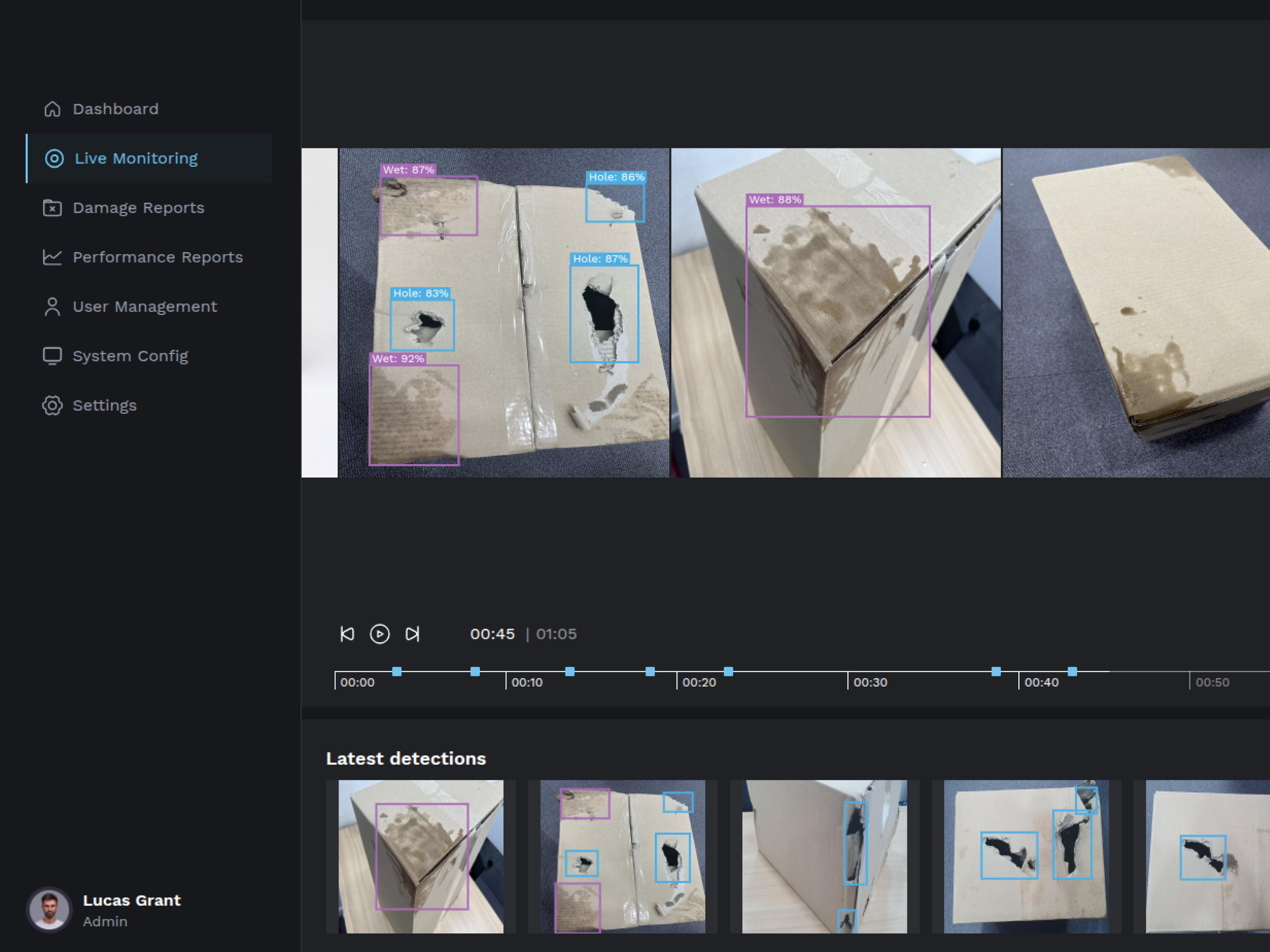

We’ve created an AI parcel damage detection system to tackle this costly challenge. It serves as an automated set of eyes in your warehouse, visually inspecting parcels in real time to catch signs of damage before they leave your facility. By deploying advanced computer vision on the conveyor line or loading dock, it flags damaged boxes (dents, punctures, water stains, and more) within seconds. So, your team can swiftly remove or rework defective packages, preventing downstream losses and ensuring customers receive orders in pristine condition. It’s like having a vigilant quality control inspector for every single parcel, only faster and tireless. And it’s easily customized to your business, creating a unique detection.

Core Capabilities

Our AI-powered damage detection solution comes with a range of powerful capabilities customized to warehouse and fulfillment workflows. From instant visual scanning to seamless integration with your existing processes, it transforms how your team ensures package quality.

Real-time parcel scanning

The system inspects parcels in real time as they move through your operations. Whether boxes are coming in on a conveyor or being staged for loading, the AI vision model analyzes each image frame-by-frame for anomalies. The moment a box with a gash, crush, or moisture stain appears, the system identifies it. This happens in seconds, far faster than a manual check, enabling immediate response. By catching issues on the fly, you eliminate the delay between damage occurrence and detection. For example, if a package with a torn corner enters the sorting line, the AI will pinpoint that defect instantly so it can be pulled for inspection or repackaging right away. This real-time vigilance means no damaged parcel goes unnoticed, keeping your operations flowing smoothly without quality compromises.

Multi-type damage recognition

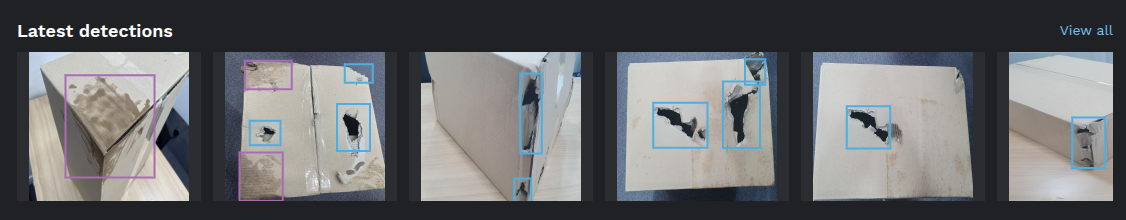

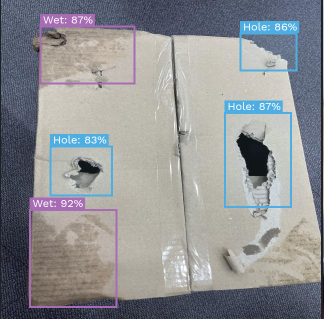

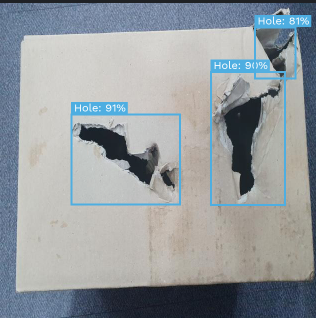

Not all damage is alike, so our solution is trained to recognize multiple types of parcel damage. Using a robust computer vision model (built on thousands of annotated images), it can detect common issues such as punctures/holes in boxes, crushed or dented edges, and water or oil stains on packaging. Instead of a simple yes/no for “damaged or not,” the system actually pinpoints where and what kind of damage is present. This localized detection helps your team understand the severity and nature of the issue at a glance. For instance, if a parcel has a visible puncture or a wet spot, the AI will highlight that specific area in the camera feed and label the damage type so staff know exactly what to look for.

This multi-type recognition is grounded in a custom-trained model that we developed using advanced AI tools. We chose a dedicated vision approach (as opposed to generic off-the-shelf classifiers) to ensure high accuracy for the nuanced task of damage detection. The model has been fine-tuned on a diverse dataset of parcel images, including different box sizes, colors, and various damage scenarios, so it performs reliably in real warehouse conditions. In practice, it achieves high precision in distinguishing true damages from innocuous marks (like printed logos or tape seams), minimizing false alarms while catching even subtle defects.

Seamless integration and alerts

Our AI inspection system isn’t a standalone gadget; it integrates directly into your existing workflow. It works with ordinary IP cameras or machine vision cameras above your conveyor belts or at inspection stations. The software can run on a local server or edge device right on-site, processing video feeds without needing constant internet connectivity. When a damaged parcel is detected, the system can trigger instant alerts through the channels that suit your operations, whether that’s a visible notification on a dashboard, a sound/light signal on the line, or even a message in your warehouse management system (WMS).

Because the solution connects with your infrastructure, the alerts can be as actionable as possible. For example, it can interface with conveyor divert mechanisms to push a flagged box off the main line automatically. Or, it can log the incident in your database, recording the package ID and damage type for follow-up. If you have an existing quality control or incident reporting system, our tool can feed data into it seamlessly.

Adaptable and continuously improving

Just like your business, our parcel damage detector is continuously improving. We understand that every operation is unique, from the kinds of packaging you use to the typical wear-and-tear items experienced. That’s why the AI model can be further trained on your specific data. As you capture more images of what “damaged” versus “normal” looks like in your environment, we can fine-tune the model to become even more accurate over time. This adaptability ensures the system stays effective even if you introduce new package types or if new kinds of defects become a concern.

Moreover, the AI’s core algorithms are state-of-the-art and benefit from ongoing advances in computer vision. Future updates can improve its capabilities, for instance, recognizing additional forms of damage (like a partially open box flap or a missing label) should those become relevant to you.

Why It Matters

Every damaged package that slips through can incur multiple costs, including product replacement, shipping a new item, handling the return, and potentially losing that customer’s future business. Stopping those shipments upfront translates into immediate savings. For example, instead of paying the cost of a broken item and expedited reshipment, you catch the issue and resolve it before it goes out. Roughly 20% of e-commerce returns occur because a product arrived damaged, meaning a significant portion of return expenses (and wasted inventory) could be avoided with better outbound quality control. By deploying our solution, companies can slash these avoidable costs. Fewer refunds and replacements directly protect your revenue, and the system often pays for itself in the value of prevented losses alone.

Also, warehouse staff might only inspect a small sample of packages, and even then, fatigue or rush can lead to missed problems. Automating this task means your team regains precious time. Instead of dedicating labor to manually checking boxes or sorting out damage after the fact, employees can focus on more valuable work, like moving goods efficiently and handling exceptions. The AI never tires or slows down, ensuring every parcel is checked with consistent vigilance. This boost in efficiency can streamline your whole logistics flow.

When damaged products reach customers, it is a hit to your brand’s reputation. A customer who receives a busted item is likely to be frustrated and may hesitate to order again. On a larger scale, frequent issues can label a company as unreliable. By ensuring that only intact, well-packaged goods leave your warehouse, you are actively protecting customer trust. Deliveries arrive as expected, leading to happy customers and repeat business. There’s also a public relations angle: preventing damage aligns with quality and care, values that enhance your brand image.

How You Can Use It

Inbound receiving teams

For receiving dock staff, the system acts as an automated inspector for incoming goods. As supplier shipments or returned packages arrive, a camera at the receiving station scans each box. If a pallet has boxes with visible dents or holes from transit, the AI flags them immediately. Your team can then take action on the spot, whether that means refusing delivery of a badly damaged item, documenting it for a claim, or routing it to a repackaging area. This ensures that upstream issues are caught at the door. Receiving teams no longer have to rely solely on quick visual once-overs; they get an assistive tool that catches what the naked eye might miss.

Outbound loading teams

On the other end of the process, shipping and loading crews use the system as a final quality gate before orders leave the warehouse. Imagine a busy loading dock where hundreds of boxes are being loaded onto trucks for delivery. Our AI is monitoring each one as it’s scanned and loaded. If any package has gotten crushed in storage or accidentally pierced during picking, the system will alert the team right then and there. The loader can quickly pull that box aside rather than sending it out. This is especially useful for preventing “hidden” damages from reaching customers. Outbound teams can trust that by the time the truck is sealed, every parcel inside has passed an AI-driven quality check. In practice, this reduces delivery exceptions: drivers won’t arrive with a box that’s visibly damaged (avoiding customer refusals at the doorstep), and your company won’t end up paying to ship a failure.

Quality assurance and operations managers

Managers overseeing quality control and operations benefit from new data and peace of mind. With the AI detection system in place, QA managers can review dashboards or periodic reports of how many parcels were flagged and why. This data might reveal trends, for instance, perhaps a particular product line’s packaging is prone to punctures, or maybe damages spike on Mondays when a certain shift is working. Such insights enable managers to dig into root causes (improving packaging materials, training staff on handling, etc.) and continually improve processes. Additionally, operations managers appreciate that the system ensures a baseline of quality without needing to micromanage every line worker. It’s like having a standardized checklist being enforced automatically. They can confidently promise high outbound quality metrics to upper management or clients because the AI is consistently auditing 100% of parcels.

Managers and executives

Beyond the warehouse floor, decision-makers and executives in the company see strategic benefits from deploying AI parcel inspection. First, there’s a clear ROI: by reducing damage-related losses and operational headaches. Executives can track key indicators like the drop in damage-related returns or an improvement in customer satisfaction scores after implementation. It’s a compelling story of innovation improving business outcomes. Moreover, adopting such technology positions the company as a forward-thinking leader in logistics. This can be communicated to stakeholders and clients, for example, a 3PL could market that they use AI inspection to guarantee shipment quality, attracting more business.

Looking Ahead

AI Parcel Damage Detection is not a one-size-fits-all widget, but a customized solution crafted to suit your company’s unique processes and goals. Every logistics operation has its own nuances, from the types of products shipped to the handling methods in the facility, and our approach is to tailor the system accordingly. We can integrate our vision tool with your existing setup: whether that means using your current CCTV cameras in the warehouse, plugging into your Warehouse Management System or ERP to log damage reports, or working alongside other automation like sorters and scanners. Our development team will fine-tune the model using sample images of your parcels and your known damage cases, so it’s perfectly calibrated to what matters most in your business (for instance, focusing on detecting liquid damage if you deal in beverages, or particular surface scratches if you ship high-end appliances).

Going forward, we are continually enhancing the capabilities of this solution. One area we’re exploring is expanding the range of detectable issues. In the future, the system could be trained to notice things like incorrectly sealed boxes, missing labels, or even perform basic checks for mis-packed orders (by recognizing if a box should contain cushioning but doesn’t, via X-ray or weight sensor integration). We also plan to refine the AI with each deployment, as it gathers more data in your environment, we can periodically retrain the model to improve accuracy and adapt to any new damage patterns that emerge. And while the current focus is visual inspection, our platform could integrate with other IoT sensors (such as shock or tilt sensors on packages) to provide a holistic view of package integrity. This means our solution is future-proof: it will grow smarter and more comprehensive over time, protecting your operations not just today but for the long haul.