Logistics

Smart Lockers and the Future of Delivery

Introduction

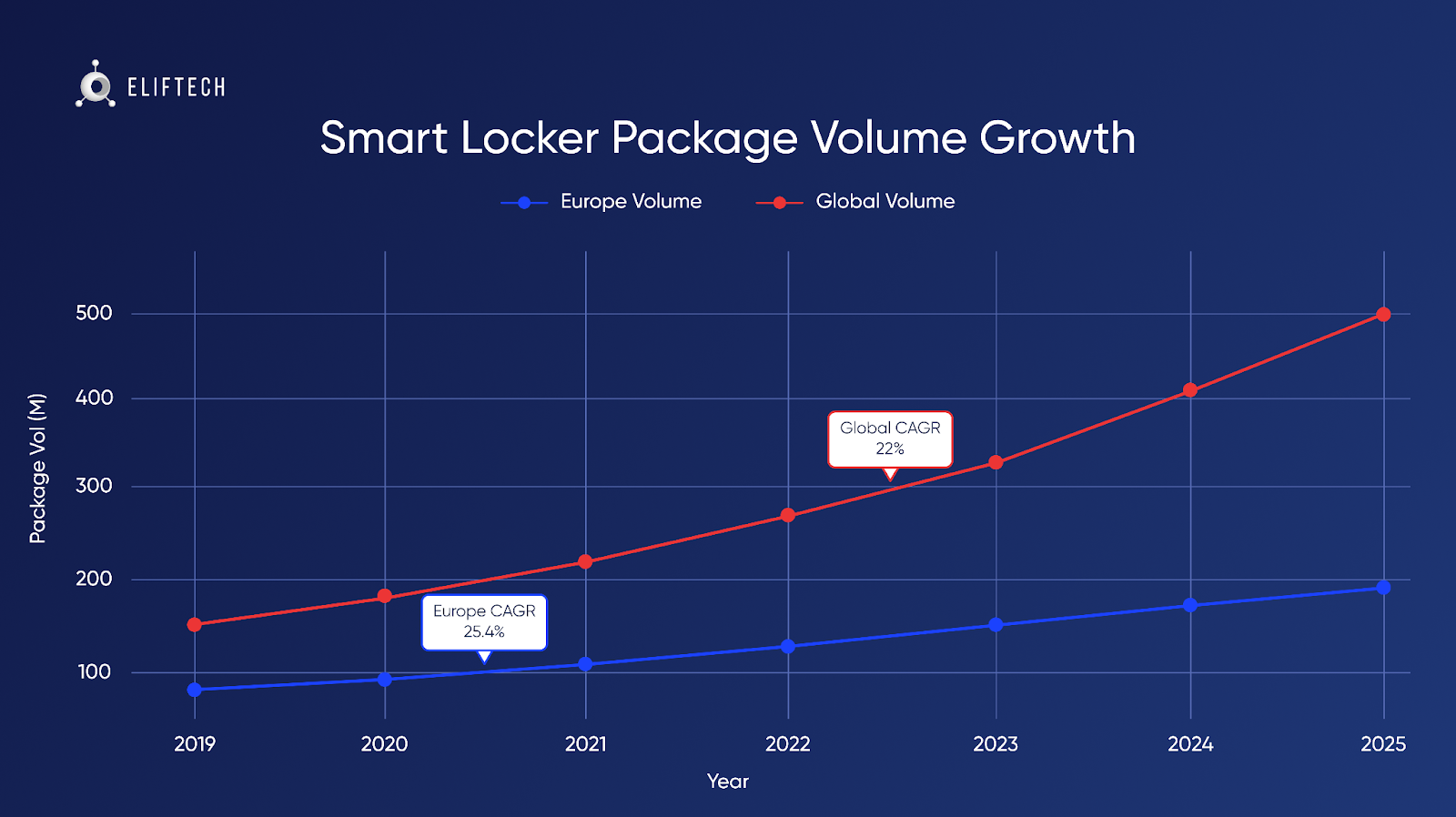

Last-mile delivery is often inefficient and costly. This final step, getting a package to the customer’s door, is usually the biggest challenge in logistics and can account for up to 53% of total delivery costs. So, why is it so expensive? Home deliveries involve many stops, which leads to high labor and fuel costs. Deliveries can fail on the first attempt; between 2 and 10% do, and it can be as high as 20% of e-commerce packages that do, resulting in costly re-deliveries and unhappy customers.

Urban traffic, new emission regulations, and an increase in online orders have added pressure to the system. Customers now expect faster and more flexible service, while couriers and retailers struggle with visibility, timeliness, and a limited number of drivers.

In short, the traditional last-mile delivery model cannot keep up with demand. A fast-growing solution is the smart locker, a technology-driven innovation that can help address last-mile delivery problems.

The Last-Mile Delivery Challenge

Even in the best of times, completing the journey from a local distribution hub to each customer’s address is fraught with hurdles. This segment is labor-intensive and time-consuming, requiring drivers to navigate congested streets for numerous small drops. The result is inefficiency at scale: multiple stops per route, idle time searching for addresses or parking, and frequent missed deliveries when recipients aren’t home. All these factors inflate costs and erode delivery performance. Moreover, modern cities are imposing new constraints – zero-emission zones and vehicle restrictions limit when and how delivery vans can access urban areas. The boom in e-commerce has also skyrocketed parcel volumes, forcing carriers to redesign processes and fleets just to keep up.

Meanwhile, customers demand real-time tracking and tight delivery windows, expecting the same convenience for a $10 item as for a $1000 item. Traditional last-mile methods, where a driver races to each doorstep, are increasingly unsustainable in terms of cost, speed, and environmental impact. The industry clearly needs a new approach to make last-mile delivery faster, greener, and more reliable.

Smart Lockers As A Smarter Last-Mile Solution

Smart lockers have emerged as an essential solution to address last-mile delivery challenges. In essence, smart lockers are automated parcel kiosks, secure compartments where couriers can drop off packages and consumers can pick them up at their convenience. Picture a wall of lockers in a train station, apartment lobby, or grocery store. Each package delivery generates a unique access code, which is sent to the customer’s phone, allowing them to retrieve their item 24/7. This simple concept eliminates the need to coordinate a meeting time or successful home delivery on the first try. Instead of a driver attempting ten individual door deliveries down a street (and potentially failing several), they can drop those ten parcels at one locker location in a single stop. This consolidation of deliveries slashes the number of trips and miles driven, cutting fuel use and avoiding repeated delivery attempts.

What makes these lockers “smart” is the technology inside. Each unit integrates networked hardware and software for secure, self-service operation. The hardware includes touchscreens, barcode scanners, electronic locks, wireless antennas, and often surveillance cameras or sensors. User-facing software enables couriers and customers to authenticate, deposit or collect parcels, make payments (for COD or fees), and even extend locker reservations, all through intuitive interfaces or mobile apps. On the backend, management software coordinates the whole locker network, handling real-time updates, access codes, inventory of free compartments, and analytics on usage. The result is an intelligent micro-warehouse within the community, one that is accessible around the clock and seamlessly integrates the digital and physical aspects of delivery. Smart lockers effectively create a small, self-serve distribution node closer to customers, redefining convenience and reliability for the last mile.

Business Benefits of Smart Lockers

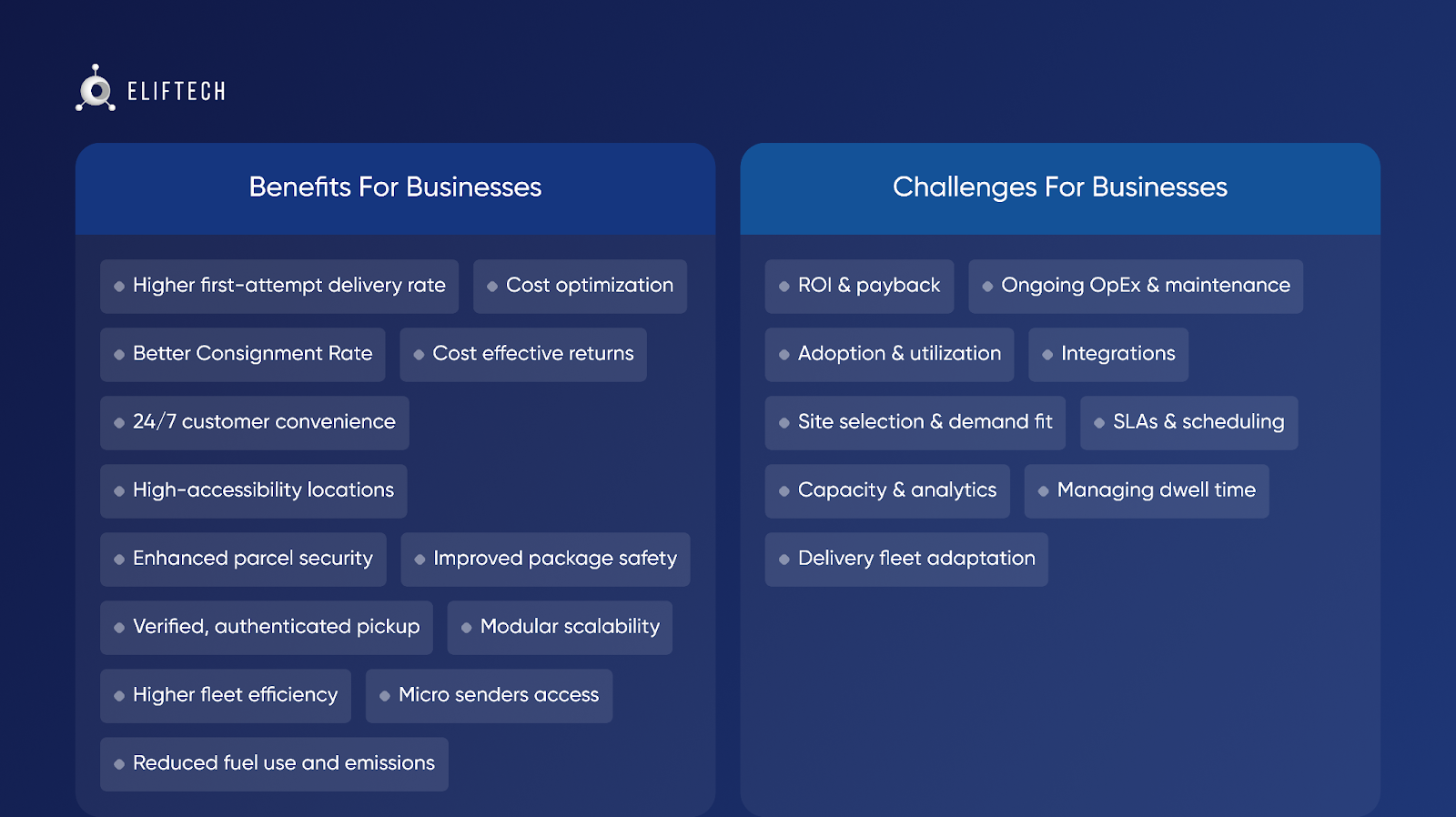

From a logistics and retail perspective, smart lockers pack a punch in delivering efficiency and cost savings. First and foremost, they drive down last-mile operating costs by streamlining delivery routes. A courier can drop off dozens of packages at a locker hub in a single trip, dramatically reducing the miles driven, fuel consumed, and labor hours per package. Fewer miles and stops also mean fewer delivery vehicles clogging the streets, which eases urban congestion and lowers carbon emissions in the process. Crucially, smart lockers also slash the rate of failed deliveries and reattempts, no more wasting time on doorsteps where no one is home. Every package waits securely for customer pickup, eliminating the costly loop of multiple delivery tries or returns.

These lockers also unlock a better customer experience, which ultimately benefits merchants and carriers through loyalty and reduced service costs. Consumers gain total flexibility: they can pick up parcels whenever it suits them, rather than being tied to a driver’s schedule. This 24/7 availability and self-service pickup significantly improve customer satisfaction and virtually guarantee delivery success on the first attempt. The added convenience comes with peace of mind; smart lockers are equipped with security features like one-time PIN codes or QR scans and CCTV monitoring, vastly reducing the risk of package theft or tampering compared to doorstep drop-offs. In an era of porch piracy, offering a secure pickup option is a competitive advantage.

Moreover, smart lockers can support new services and revenue opportunities. Retailers use them for click-and-collect orders, returns processing, or even local inventory storage for fast deployment. A network of lockers in strategic locations (residential complexes, transit hubs, office parks) expands a company’s delivery footprint without the expense of new stores or branches. Consolidated drop points also mean faster delivery cycles, enabling same-day or next-day delivery promises to be met more easily. Some locker operators and logistics providers leverage usage data, parcels per day, peak pickup times, and dwell times to optimize operations and even inform business decisions with data-driven insights on consumer behavior. Finally, by reducing fuel burn and van trips, companies not only save money but can also shrink their carbon footprint, supporting sustainability goals and compliance with green regulations. In sum, smart lockers can turn many of the last mile’s liabilities, failed drops, high costs, and slow service into strengths, offering a win-win for businesses and customers alike.

Technology Enablers Behind Smart Lockers

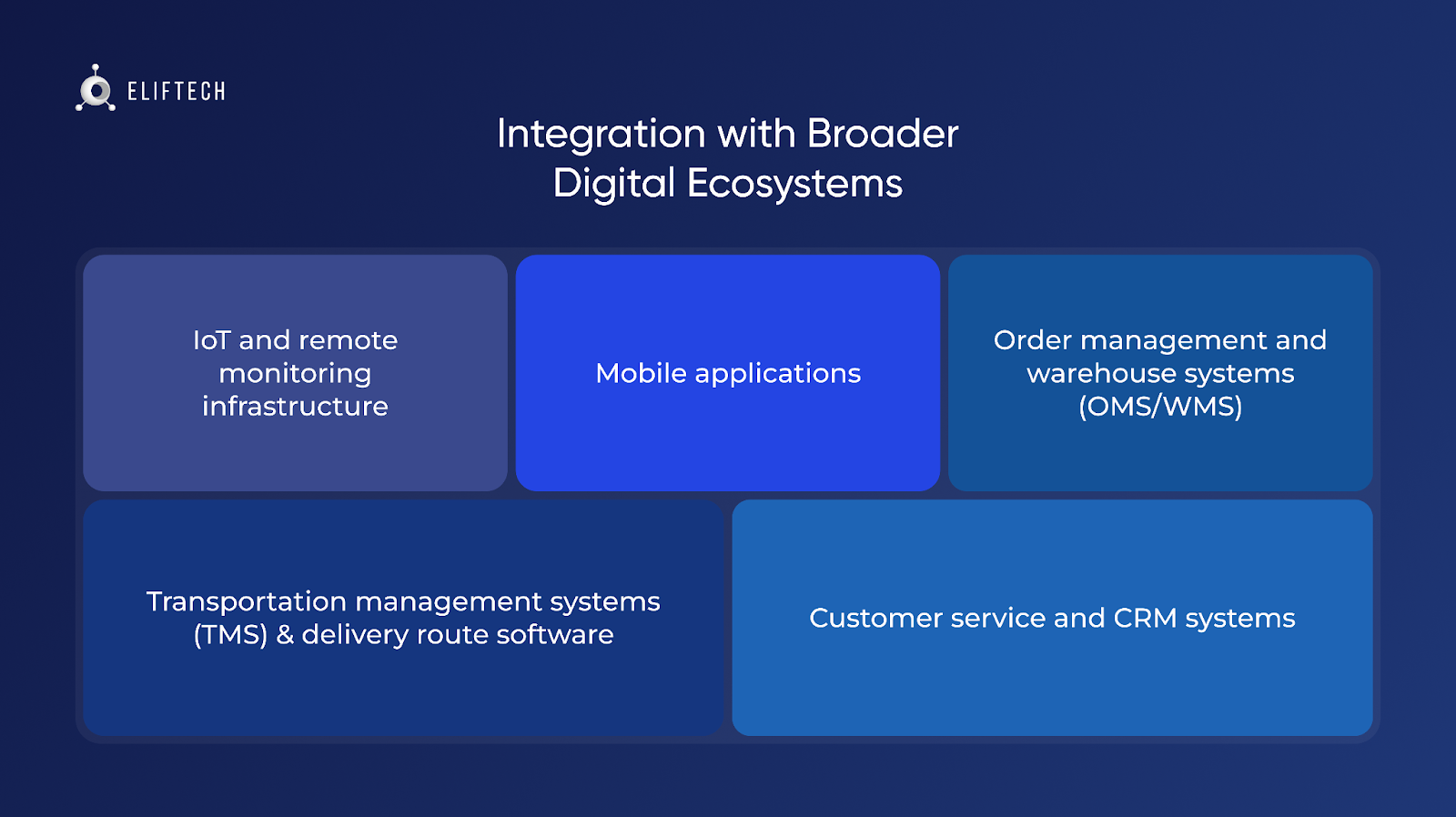

Smart lockers owe their effectiveness to a convergence of advanced technologies that power their “smarts.” At the core is the Internet of Things (IoT); each locker unit is an IoT device, embedded with sensors and connected to the internet for continuous communication. These sensors monitor locker status (occupied or empty compartments, door open/closed), detect any tampering, and even track environmental conditions for temperature-controlled units. This wealth of real-time data is relayed to cloud platforms, enabling live status updates and alerts for operators. If a locker is nearing full capacity or experiences a fault, managers know instantly. IoT-driven monitoring also enables predictive maintenance: the system can flag issues (a failing lock mechanism or low battery, for example) before they cause downtime, so technicians can fix proactively.

Another key enabler is the cloud infrastructure that connects all lockers into a unified network. Modern smart locker systems are cloud-managed, meaning updates to software, access permissions, or system configurations can be rolled out remotely across hundreds of units. This cloud-based integration makes it far easier to deploy and scale a locker network without on-site IT for each unit. It also allows seamless integration with other logistics IT systems, for example, as soon as a courier secures a parcel in a locker and scans it, the cloud backend updates the shipment status and pings the customer with pickup details. All stakeholders see a synchronized, real-time picture of deliveries in flight.

On top of IoT and cloud, AI and analytics play a growing role in smart locker strategy. AI algorithms can crunch the data coming from locker networks and identify patterns, which locations see the heaviest use, what times of day lockers fill up, which locker sizes are in highest demand, etc. These insights help in optimizing locker deployments and operations: companies can strategically choose new locker sites, right-size the number of compartments, and even adjust delivery routing based on predicted demand. AI models are also being explored to dynamically route urgent shipments to locker or drone delivery depending on conditions, adding a layer of intelligence to last-mile decisions. Finally, the digital user interfaces enabled by mobile apps and modern authentication tech make the system user-friendly and secure. Customers interact with lockers through smartphone apps or SMS codes, and many lockers now support biometric ID, RFID badges, or QR code scanning for quick access instead of clunky keys. End-to-end encryption and secure cloud authentication ensure that only the intended recipient can open their compartment, addressing data privacy and security concerns from the ground up.

Integration Requirements for Locker Deployments

Implementing smart lockers is not as simple as dropping metal boxes on a sidewalk; successful integration requires careful planning on both technical and physical fronts. Systems integration is often the first hurdle. Legacy Transportation Management Systems and warehouse software were never designed to interface with automated lockers, so logistics IT teams must bridge that gap. In many cases, companies need to develop custom API connections or middleware to link the locker management platform with existing order fulfillment, tracking, and notification systems. Every locker drop-off should trigger updates to multiple systems (inventory records, customer alerts, driver workflow), which means the data flows must be seamless and in real time. Any delay or disconnect, for example, between the locker system and the courier’s handheld app, can result in lost parcels or failure to notify the customer, undermining the very efficiency the lockers aim to provide. Robust integration also extends to data security and privacy compliance. Since lockers handle personal data (like recipient information and access codes), solutions must employ end-to-end encryption, secure user authentication, and compliance with regulations (GDPR, CCPA, etc.) to protect customer information. IT architects must incorporate these security requirements when weaving lockers into the enterprise network.

Beyond the software, there are practical installation requirements. Smart lockers need a suitable location with the right infrastructure: a power supply for the electronic locks and screens, and reliable network connectivity (whether via Ethernet, Wi-Fi, or cellular) to keep the locker online. Placement is strategic; lockers should be situated in high-traffic, easily accessible areas that align with user routines, such as apartment lobbies, office campuses, transit stations, or retail centers. Planners often conduct surveys or use AI models to determine optimal sites that maximize convenience and parcel volume. Physical security is another integration factor: units might need shelter from weather if outdoors, adequate lighting, and even positioning within view of existing security cameras. Locker banks can be sizable, so securing permission and space from property owners or municipalities is part of the rollout plan. Finally, there’s an integration with human processes; couriers need to incorporate locker deliveries into their routes and receive training on using the systems. Customer service teams must be ready to handle questions or issues (for instance, if a locker door fails to open via the code, or if a customer is late to pick up a package). In short, deploying smart lockers touches many parts of the business, requiring a holistic integration effort where technology, infrastructure, and people all sync together.

Operational Considerations and Best Practices

Once smart lockers are up and running, companies must manage them smartly to reap the full benefits. Maintenance and uptime become critical considerations; even the smartest locker is useless when it’s offline or jammed. Without proper planning, locker hardware can become an unexpected cost center if units break frequently or require too much manual attention. Common issues include door mechanism failures, network outages, or software glitches that lock users out. Such incidents can bring last-mile operations to a halt, as packages sit inaccessible. To combat this, leading locker operators implement proactive maintenance protocols. IoT sensors and self-diagnostic software continuously check each locker’s health, triggering automatic alerts if something deviates from normal (e.g., a door that didn’t close properly or a control board not responding). Companies schedule regular inspections and software updates during low-use hours to prevent breakdowns. Just as important is having a quick response plan, a mobile tech team on call to fix problems or open lockers manually in an emergency, minimizing downtime. By staying ahead of maintenance, operators can keep reliability high and avoid eroding customer trust.

Another operational key to success is training and process standardization. Introducing smart lockers alters how drivers, warehouse staff, and customers behave in the delivery chain. Couriers must be trained in the new workflow, scanning packages into lockers, inputting data correctly, and perhaps assisting first-time users on site. Standard operating procedures should be defined for scenarios like when a locker is full or a package has remained uncollected beyond the pickup window. As one industry guide notes, even the best technology can stumble without the right processes behind it; investing in comprehensive staff training and clear protocols is essential to realize the efficiency gains lockers promise. Customer adoption is equally important. The best locker network achieves nothing if consumers won’t use it. Building awareness and comfort with the locker option is an ongoing operational task. Shippers need to be able to list the locations and services of their carrier partner networks clearly and with full confidence that the listing is up to date. Logistics providers often need marketing efforts and incentives to nudge customers toward choosing locker delivery at checkout. Public education initiatives can spotlight the benefits, for example, emphasizing how lockers offer contactless, anytime pickup, thereby driving greater usage. In some markets, governments and postal authorities have stepped in to help by rolling out nationwide locker networks and even subsidizing installations, recognizing that widespread adoption can reduce urban delivery traffic and emissions.

Finally, companies should continually analyze and refine their locker operations. Data on locker utilization can reveal if certain locations are underused (perhaps indicating a need to relocate those units) or if certain times see spikes in activity, suggesting when to add capacity or send restocking personnel (for outbound shipments or returns). Some sectors might require specialized locker features, for instance, temperature-controlled lockers for groceries or medical supplies, or extra-large lockers for bulky items, which need to be factored into operational planning. A flexible, modular approach allows the locker network to scale and adapt with business growth and seasonal demand. By addressing these considerations, maintenance, training, user adoption, and continuous optimization, organizations ensure that smart lockers deliver on their promise of a faster, smarter last mile.

Delivering a Smarter Last Mile

Smart lockers are proving to be a pivotal innovation in last-mile delivery, turning an array of logistical challenges into opportunities. By rethinking how and where parcels are handed off to customers, lockers fundamentally increase efficiency, reduce costs, and enhance service reliability. They leverage technology to bridge the gap between e-commerce’s digital convenience and the physical realities of moving goods the final few miles. The result is a more agile last-mile model: one that scales with booming delivery volumes, meets sustainability targets, and satisfies consumers’ demand for quick, secure, convenient service. To be sure, making the locker model work requires investment in integration and careful operational management. But for those logistics providers and retailers willing to embrace change, smart lockers offer a pathway to last-mile excellence, a future where deliveries are as smooth and predictable in the final mile as they are in the first. The last mile may always be the hardest step in delivery, but with smart lockers, it no longer has to be a weak link in the supply chain. Instead, it can become a competitive differentiator and a cornerstone of modern, customer-centric logistics.