Logistics

The Future of Supply Chain 2026

Introduction

In 2026, the supply chain industry will face new pressures and opportunities. Volatility and uncertainty in logistics are the new normal. The pace of change is accelerating. Driven by technological advancements, climate challenges, geopolitical shifts, and more, the "future of supply chain" is continuously redefined.

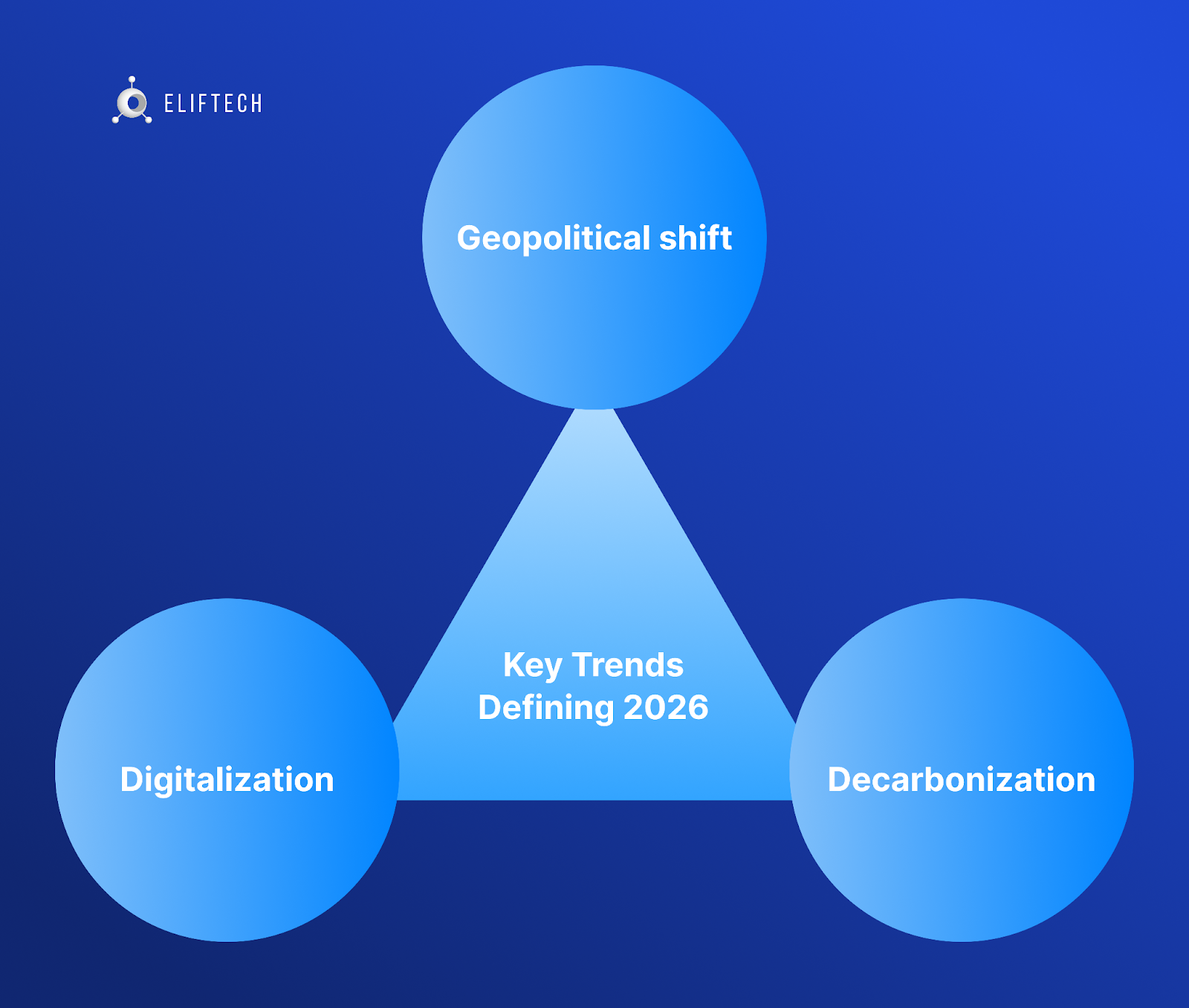

Wolfgang Lehmacher, a supply chain, logistics, and technology adoption expert, has shared with us his insights on the key trends shaping the industry in 2026 and how supply chain and logistics teams can prepare for the changes ahead. He emphasises three well-known key shapers of supply chain and logistics networks: digitalization, decarbonization, and decoupling. These trends drive the growing need for agility and data-driven decision-making through enhanced, augmented human-machine interaction. The article also outlines the factors that set successful organizations apart, including how actors with limited budgets can stay in the game.

Key Trends Defining 2026

Digitalization.

The supply chain industry moves from basic automation to intelligent AI-driven “agents” that can autonomously orchestrate operations. 75% of global executives rank AI as their top supply chain investment priority for 2026. We see AI-powered forecasting, real-time visibility, and continuous risk and resilience management becoming mainstream. Digital tools are no longer optional add-ons. They are essential to remain competitive. Companies that adopt digital integration at scale and understand data-driven decision-making as a habit will operate with unmatched speed and precision.

2026 forecast: Digitalization will further accelerate and evolve.

Principal response: More experiments, pilots, implementation, and integration.

Decarbonization.

The pressure to reduce emissions and "green" supply chains will only increase over time. Industry expert Wolfgang Lehmacher predicts a "two-speed" approach to sustainability: some regions will slow their efforts by 2025 due to delays in some regulatory measures and decarbonization strategies, while in other places we will see an acceleration of the initiatives. The expert does not doubt that, over time, environmental regulations and customer expectations will accelerate the logistics industry’s transition toward cleaner technologies and the reduction and ultimately the elimination of the negative, unwanted consequences of linear practices. Climate action is shifting from mere compliance to a competitive advantage for leading companies. We can expect increased investment in alternative fuels, electric fleets, and circular supply chain models, including return and reverse logistics programs, although progress may vary across different markets.

2026 forecast: A heterogeneous picture of overall growing spending in sustainability.

Principal response: Alternative fuels, electrification, and clean technologies are on the rise.

Geopolitical shifts.

Geopolitics continue to reshape supply chain networks. Ongoing trade tensions and tariff uncertainties compel companies to diversify their supplier base and regionalize production to reduce risk and raise resiliency. In 2026, this trend of “decoupling” from single-country sourcing and reliance (notably China) persists, through nearshoring, friend-shoring, and building more resilient multi-region networks. Global trade is not disappearing, it is evolving; major logistics players note that regional supply chains can grow even as international trade remains robust. The key to success is balance: having multiple sourcing options to boost resilience while still capturing global market growth.

2026 forecast: Uncertainty caused by geopolitical tensions and changes in foreign policies

Principal response: Continuous diversification of sourcing and supply chain optionality.

Preparing Organizations for 2026

To stay competitive in 2026, organizations must focus on building agility, resilience, and a people-centric culture. The supply chain industry changes fast, so companies need to be prepared to “learn and unlearn quickly” as new configurations, policies, and disruptions arise. Preparedness begins with an open and agile mindset: encouraging continuous adaptation, scenario planning, and “always-on” monitoring of your supply chain. Many organizations are moving away from static annual plans to continuous planning cycles, updating forecasts and plans in real time as conditions change. This level of responsiveness can be crucial, enabling teams to absorb shocks and react to changes and supply chain shocks faster than their competitors.

At the center is the human factor. In an era of increasing automation, successful companies will invest in their employees and cultivate an open, nimble, and innovative culture. Technology initiatives should be paired with upskilling programs: if we invest one dollar in technology, we should invest one dollar in people. Frontline staff and planners must be trained to work effectively with new digital tools. Moreover, managing the human-machine interplay is essential; machines should handle repetitive tasks while empowered humans focus on strategic and creative problem-solving. Tools should improve team performance, not overwhelm the teams. Successful change requires buy-in. By involving employees early in the process, addressing their concerns, and demonstrating how technology can simplify their work, organizations can create a culture that is curious, open, and excited about technological transformation.

Involvement, tech implementation, and integration will be vital for success in 2026. This will naturally break down silos and ensure that data flows seamlessly and in a controlled way within organizations and supply chains across departmental and company borders. Digitalization provides end-to-end visibility, is a prerequisite of automation, and the foundation for data-driven decision-making, another key trend identified for 2026. This allows companies to know exactly where their inventory is, forecast demand, anticipate disruptions before they occur, and rebalance inventory when needed. Close collaboration with suppliers, customers, and logistics providers, including the sharing of data and insights, will improve the quality of responses and enhance the responsiveness of entire supply chain ecosystems. Organizations that have established a proactive, tech-enabled, and people-driven culture and mode of operating are well prepared for 2026. Those who have not are advised to catch up with their peers or become the pioneer who will lead.

Technology’s Role in 2026

Artificial intelligence & automation.

AI is transitioning from pilot programs to widespread deployment. It is increasingly used in areas such as demand forecasting, route optimization, and warehouse automation, where AI systems are starting to make decisions that once required human knowledge and experience. We are witnessing a shift from automation to agency, meaning that autonomous AI agents may soon be able to manage supply chain tasks from start to finish. This could involve AI chatbots processing customer orders, machine learning models dynamically adjusting inventory levels, and intelligent robots operating in distribution centers.

Capturing the opportunity requires integrating the AI solutions with existing legacy systems and workflows. Companies that effectively incorporate AI into their operations can achieve increased speed, cost savings, and improved accuracy. AI-powered analytics can facilitate real-time rerouting during disruptions, while automating routine decisions allows humans to concentrate on more strategic tasks and exceptions.

Data analytics & visibility.

Data is often referred to as the power of the supply chain. In 2026, using data will be crucial for businesses. Advanced analytics, control towers, and digital twins (virtual models of the supply chain) will enable companies to run simulations and respond swiftly to changes and disruptions. With vast data streams generated by IoT (Internet of Things) sensors, telematics, and transactions, logistics teams can gain a real-time view of shipments and inventory. The goal is to achieve complete end-to-end visibility, a full picture of the suppliers' chains, not just knowing your first-tier suppliers. Visibility and traceability have become fundamental customer expectations and prerequisites for navigating turbulent times. Those who effectively harness data-driven insights can anticipate challenges, such as supplier delays or sudden demand spikes, and take action before customers are affected.

Sustainability technology.

Technology plays a crucial role in reaching emissions targets. We can expect broader adoption of route optimization software to reduce fuel consumption, as well as accelerated adoption of electric vehicles in some parts of the world, particularly Europe. In Africa, e-mobility is already recasting the logistics and delivery landscape in Africa’s cities, emerging as one of the continent’s most credible opportunities to leap ahead rather than catch up. It is doing so not with heavy trucks, but with nimble electric two- and three-wheelers, cargo bikes, and light commercial vehicles better aligned with the realities of African urban transport. Additionally, smart energy management systems in warehouses and innovative "clean tech" solutions in materials and packaging will become more prevalent.

Technology and data are also vital in addressing geopolitical and environmental challenges. Systems continuously monitor risks, such as weather changes, port closures, and political unrest, and adjust plans accordingly. In 2026, forward-thinking companies will approach sustainability as a technology-driven initiative, measuring carbon footprints in real time and utilizing analytics to identify improvements that benefit both their business and the planet.

Human-centric automation.

In 2026, technology will not replace people; it will make them better. Successful logistics teams will utilize tools such as AI-powered analytics alongside human judgment. AI can analyze millions of data points to recommend optimal inventory allocation, but managers will rely on their experience to validate and implement these changes. As mentioned earlier, it is crucial to keep the workforce engaged with new technology adoption. Modern user interfaces, collaborative robots (or "cobots"), and AI assistants should be designed to excite and empower people, both within the company and those who deal with it. Companies that thrive will be those that effectively combine the efficiency of machines with the creativity and adaptability of humans.

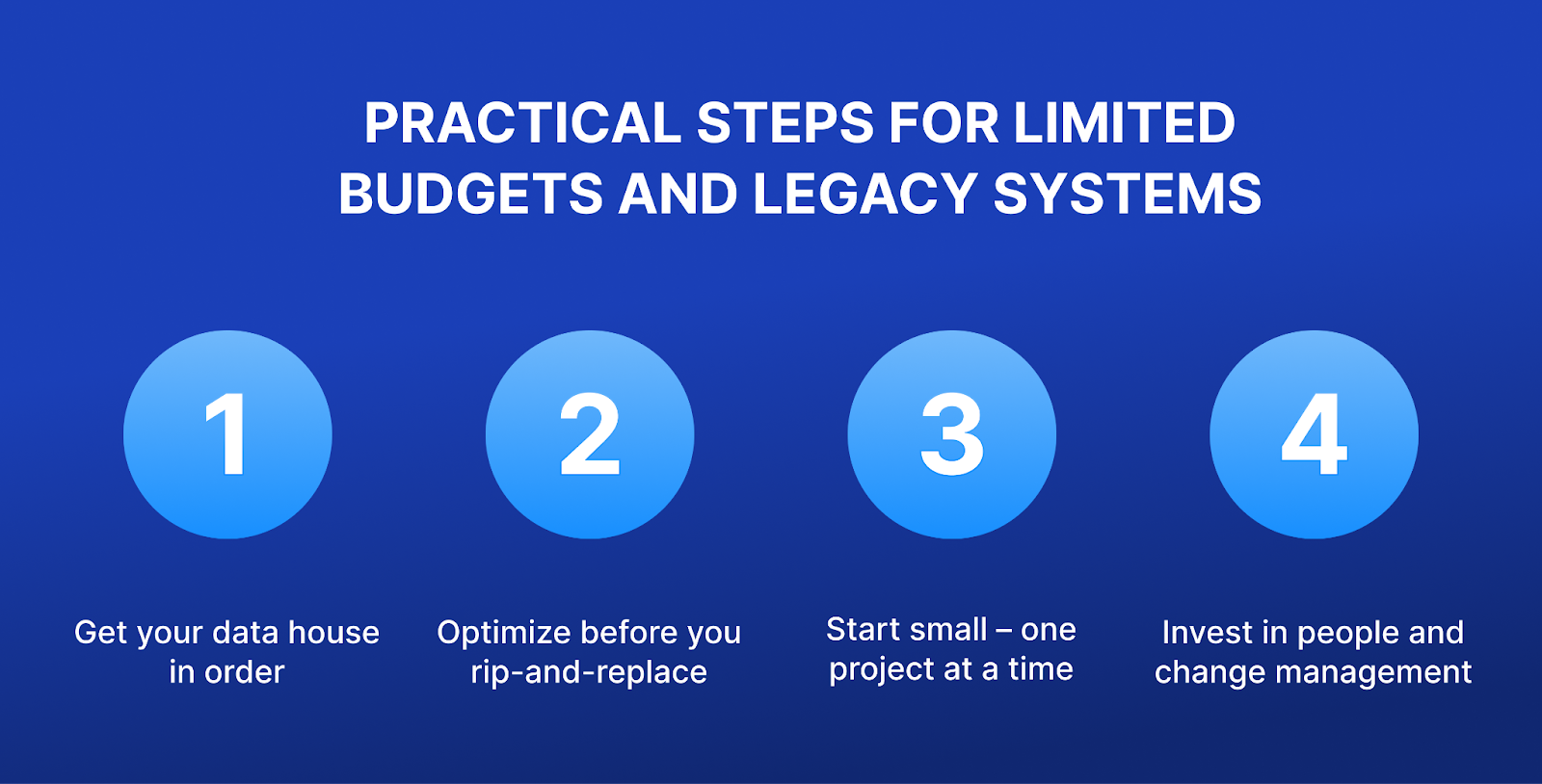

Practical Steps for Limited Budgets and Legacy Systems

Not every organization has a Fortune 500 budget or the luxury of a blank-slate IT environment. Many logistics companies are dealing with tight budgets and aging legacy systems. Yet, they can still keep up with the challenges ahead in 2026. You do not need unlimited resources to make meaningful progress and stay in the game.

What do you need to know?

1. Before investing in new technology, prioritize your data. It is essential to prioritize data by sorting and structuring it effectively. Begin by eliminating data silos, improving data quality, and ensuring you capture the right metrics from your daily operations. Even if you have legacy systems, you should standardize your data and integrate spreadsheets or databases for better analysis. Consider using low-cost tools or even generative AI assistants to help organize and interpret your data. This approach can quickly reveal opportunities for improvements and process optimization without significant effort and spending. Good data is the foundation of any successful digital initiative.

2. If a complete systems overhaul is not within your budget, consider ways to improve your existing systems. Often, there are affordable add-on solutions or middleware that can extend the life of legacy software. You might implement a modern analytics dashboard on top of an old ERP (enterprise resource planning) system to gain better visibility, or use a robotic process automation (RPA) tool to automate data entry tasks. The idea is to improve old systems rather than replace them immediately. This could involve utilizing cloud services or APIs to connect older systems with new features. The goal is to upgrade without uprooting your current setup, maximizing the value of what you have got through targeted technological enhancements.

3. Go step by step. Focus on one impactful area and pilot a one-use-case improvement. It is about doing one thing at a time, one case, one quarter, one proof of concept. You can choose one pain point, such as delivery route planning, invoice accuracy, or inventory accuracy, and concentrate on enhancing it this quarter. Within a narrow focus, you can experiment and learn quickly without incurring significant risks.

4. One of the most cost-effective strategies is to invest in your team. Training staff on new digital skills, fostering a culture of innovation, and involving employees in improvement projects can yield significant returns. Companies can upskill their workforce without making large tech expenditures by utilizing online courses, encouraging cross-functional projects, or partnering with technology providers for workshops.

Always engage employees from the beginning when introducing any new tools or processes. Their buy-in and feedback are critical and save you time, money, failures, and frustrations. Often, frontline workers have practical ideas for optimizing workflows.. A motivated, tech-savvy team can significantly improve the effectiveness of the tools already at their disposal, bridging the gap until larger upgrades are feasible.

Investing in talent and cultivating a culture that embraces change is just as crucial as any hardware or software implementation.

Conclusion

In 2026, supply chain management will be even more progressive. Logistics and supply chain management teams should pay attention to the three key trends, known as the 3Ds, and thoroughly evaluate their preparedness. Is your organization agile and data-driven? Are you effectively using technology while engaging your team in the process and software implementation?

Preparedness is not a question of budget but of necessities. A lot can be achieved with limited resources. By empowering people and embracing digitalization and technology, we can commit to sustainable practices, mitigate geopolitical and market shocks, and lay the foundations for a future-proof enterprise.

In 2026, the leaders are those who move quickly, learn continuously, and prioritize people within an increasingly high-tech logistics and supply chain world.