Logistics

Why Mid-Size Logistics Companies Lose Millions to Fragmented Systems

Introduction

Mid-sized logistics providers operate in a high-pressure environment of tight margins and a universe of complex supply chain networks. Yet many of these firms rely on a patchwork of disconnected connectivity solutions, software, and processes. This fragmentation involves using multiple systems that don’t communicate with each other, such as separate tools for warehouse management, transportation, inventory, and accounting, each focusing on its own silo. At first glance, a few extra spreadsheets or standalone apps might not seem to be a big deal, but “beneath the surface, disjointed systems and siloed processes quietly erode profitability, slow down decision-making, and increase risk exposure”. As the unintended result of growth, fragmentation has become very common. As companies expand or adopt new tools, they “begin to accumulate disconnected systems” that turn quick fixes into long-term inefficiencies and risks.

About 70% of digital transformation efforts fail to meet expectations, with poor system integration being a leading cause. Moreover, lack of integration undermines one of logistics providers’ top goals: visibility. One global survey found that only 6% of companies have achieved complete supply chain visibility, a disturbingly low figure given that nearly 70% list real-time visibility as a strategic priority.

What Fragmentation Looks Like

In a fragmented logistics operation, everyday work is hindered by manual processes and redundant data entry. Each department might use its own software, such as one for tracking orders, another for inventory, and another for fleet management; none of which sync with each other. Employees end up acting as the “glue” between systems. A fulfillment team might juggle three different platforms for orders, stock levels, and shipping. If one system isn’t updated, someone must scramble to reconcile the data by hand. This is an error-prone process. Teams often enter the same information multiple times across multiple systems, or hunt through spreadsheets and emails to find the latest status. This isn’t just annoying, it’s actively harmful. One industry survey found that 50% of professionals waste over 10 hours each week searching for or duplicating information due to such disconnected systems. That’s more than a full workday lost per person, per week, just to bridge the gaps in a fragmented landscape of tools.

A fragmented setup also creates silos of data. Front-line staff may not benefit from a single source of the truth that provides a holistic view of inventory levels, customer orders, and delivery statuses, but rather face a scattered reality as data resides in separate databases. As a logistics technology consultant described it, “outdated systems that don’t talk to each other are not only frustrating, they hold your business back and lead to siloed data, manual workarounds, and delays that cost you time and money”. In practical terms, this could mean a warehouse manager doesn’t see an urgent order that came in through a separate sales system, or a dispatcher manually re-types delivery details from an email into a routing tool. Individually, these workarounds might seem minor, but together they create widespread operational drag. The organization slows in its responses to customers’ requests, and even minor errors (a missed update or a misplaced decimal) slip through cracks between systems. This is what fragmentation looks like on a day-to-day basis: duplicate work, inconsistent data, and a lot of “checking again” to ensure nothing falls through the cracks.

Why Mid-Sized Firms Are Hit the Hardest

Organizations of all sizes face system fragmentation, but its effects often hit mid-sized logistics companies the hardest. There are a few reasons for this. First, mid-sized firms have typically grown beyond the simplicity of a small operation; they may manage multiple distribution centers, serve numerous clients, or coordinate across regions, yet they lack the massive IT budgets of large enterprises to integrate all their operations seamlessly. Historically, the most robust logistics software (like advanced Transportation Management Systems or Enterprise Resource Planning (ERP) systems) was built and priced for very large shippers, leaving mid-tier players underserved. As one industry analyst noted, “mid-tier shippers have long been underserved by software vendors that were more focused on larger customers”. In practical terms, a mid-sized 3PL or carrier may not be able to afford a top-tier all-in-one platform, so they often end up patching together affordable point solutions for different needs.

Cost is a significant factor. Implementing an enterprise-grade integrated system can be prohibitively expensive for mid-sized companies, both in terms of software licenses and the change management effort required. If a world-class logistics ERP system seems out of reach, companies may opt to stick with what they have, even if that means relying on fragmented legacy solutions and spreadsheets. Over time, you end up with a mix of old and new technologies that don’t fully integrate. Indeed, many mid-sized logistics providers find themselves using “outdated systems that don’t talk to each other” and missing key features they need. Unlike global giants, they often can’t justify the high upfront investment to replace all systems at once, and unlike small startups, they can’t run things on simple manual methods anymore. The mid-sized segment is caught in the middle.

Another challenge is that successful mid-sized enterprises grow rapidly or through acquisitions, leaving them with a blend of processes and software that have been inherited over time. Each new warehouse or business line might introduce its own application. What starts as necessary quick fixes (“let’s add a scheduling app for our new cross-dock facility”) accumulates into a fragmented architecture. As one report puts it, “fragmentation is often the unintended result of growth,” as new geographies or tools introduce disconnected systems that “slowly calcify into structural inefficiency.” Large enterprises typically have dedicated IT teams to integrate or standardize these systems. Still, mid-sized firms often have a lean IT team that must juggle daily firefighting, leaving little bandwidth to overhaul systems. The result: mid-sized logistics companies often operate at enterprise-level complexity on a patchwork infrastructure. They feel the pain of fragmentation acutely: every delay or error directly impacts their narrow margins, yet they haven’t had the resources or guidance to break free from it until recently.

Paradoxically, mid-sized enterprises also have less cushion to absorb the costs of fragmentation. A global 3PL might survive inefficiencies through sheer volume and capital, and a small local forwarder might stay simple enough to avoid significant issues. But a mid-sized logistics provider dealing with thousands of orders and multi-step supply chains can waste substantial money if things aren’t running optimally. For instance, studies show that nearly 60% of small and mid-sized businesses have lost up to 15% of their revenue due to supply chain delays and disruptions. Mid-sized logistics firms often serve businesses or operate similar supply chains. When fragmented systems cause delays (such as missing a delivery appointment due to a communication gap), the financial impact is very real. In short, mid-sized companies have grown complex enough that fragmentation costs millions, but they have historically lacked the same support and systems as their larger peers to tackle it. When fragmented systems cause delays, such as missing a delivery appointment due to a communication gap, the financial impact is very real. In short, many mid-sized companies have grown complex enough that fragmentation costs millions, but they have historically lacked the same support and systems as their larger peers to tackle the challenge.

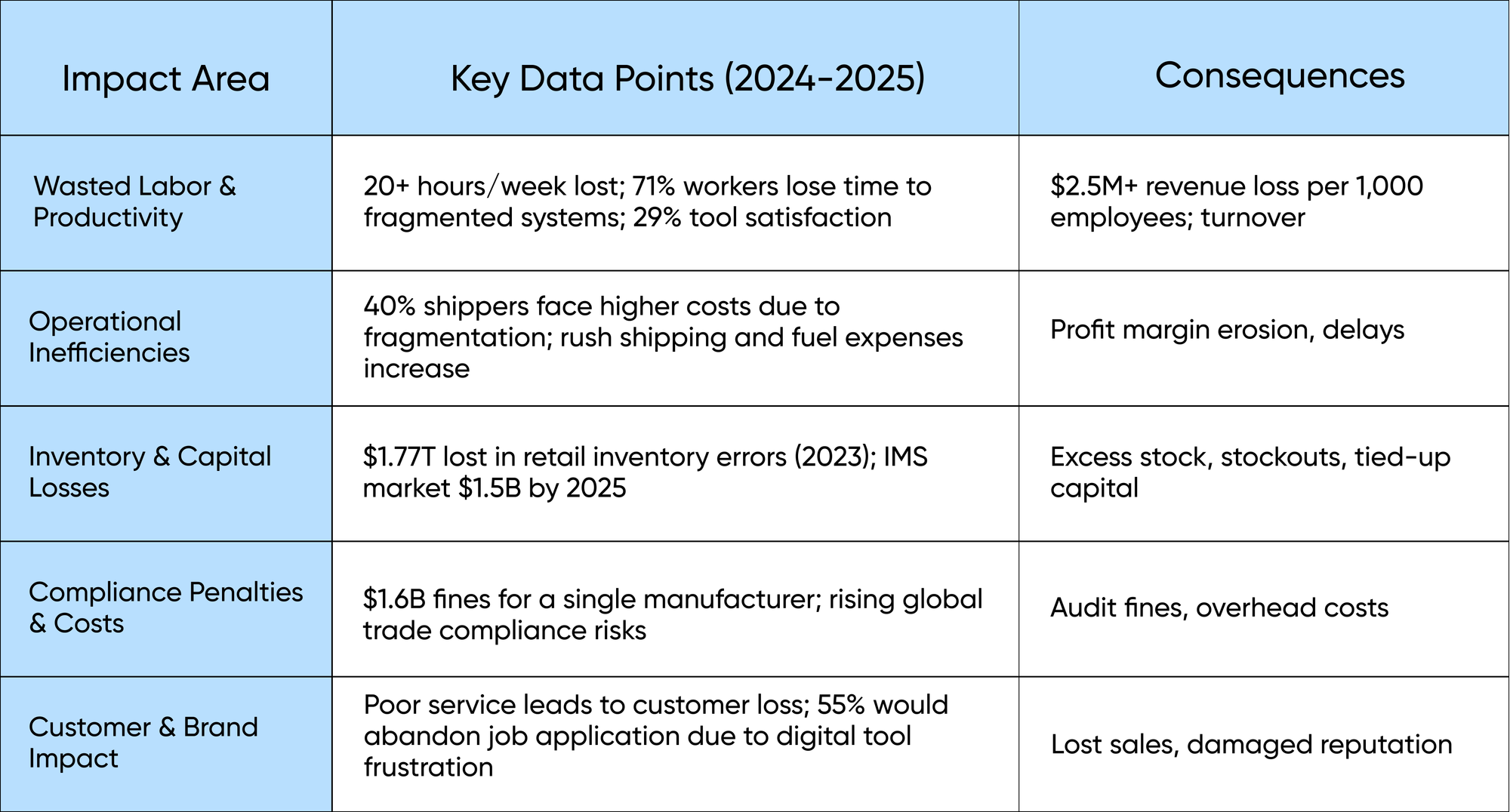

The Real Costs of Fragmentation

What does all this fragmentation actually cost mid-size logistics companies? The losses come in many forms, some obvious, some hidden, but they all add up to a significant drain on profitability. Here are the key cost areas:

Wasted labor and lower productivity

Fragmented, non-integrated systems require employees to spend significant time on manual, repetitive tasks, such as data entry and record verification. Recent studies show that workers lose over 10 hours a week, more than half their workweek, just chasing information across disconnected tools and platforms, which translates to millions of dollars waste annually. This inefficiency leads to costly errors, such as misdirected shipments and billing mistakes, and to digital fatigue that drives employee frustration, lower morale, and higher turnover rates. Only 29% of organizations reported satisfaction with their current digital tools in 2024, down from 40% in 2022.

Inventory and working capital losses

Without integrated visibility across inventory, businesses face overstocking or stockouts. Retailers lost an estimated $1.77 trillion in 2023 due to inventory mistakes stemming from fragmented data. Mid-sized logistics companies experience tied-up capital due to excess inventory and lost sales resulting from stock shortages. The inventory management system market is growing to address these challenges, projected to reach $1.6 billion by 2026.

Compliance penalties and errors

Fragmented reporting and tracking systems increase the risk of non-compliance with evolving global trade and other regulations. In 2024, unprecedented compliance penalties underlined the importance of integrated trade and logistics systems to avoid costly audits and fines. Even compliance management overhead in fragmented environments imposes significant operational costs.

Lost customers and brand damage

Delayed deliveries and inaccurate information degrade customer satisfaction in a market where service expectations are higher than ever. Fragmentation-driven operational failures risk driving away customers and damaging a brand's reputation, particularly for mid-sized firms that struggle to meet commitments reliably.

How to Break the Fragmentation Trap

1. Map and assess your current state

The first step is understanding where fragmentation exists and how it impacts operations and the organization. Conduct a thorough needs assessment of your logistics processes and tools: identify all the software, spreadsheets, and manual workflows in use across departments. Audit provides a clear picture of which gaps, if plugged, would yield the most significant efficiency gains. Common trouble spots for mid-sized enterprises include unexpected shipping costs, limited to no inventory visibility, and difficulty coordinating with multiple partners.

2. Define an integration roadmap

Next, prioritize which systems or processes to integrate first based on the impact and feasibility. It may be overwhelming to connect everything at once, so focus on the critical workflows. Define precise requirements: Do you need a centralized platform to replace multiple tools, or can you use APIs or middleware to integrate them? Additionally, consider future growth and select solutions that can scale with your needs. Many mid-sized companies improve integration by streamlining their software stack; instead of using 10 disparate programs, they move to fewer, more comprehensive platforms.

3. Implement advanced integration technology

Breaking down fragmentation is now much easier than it was a decade ago. Cloud-based software and integration tools can connect systems without the need for massive on-premises projects. You can use a centralized “operational layer” that unifies data from different sources.

4. Standardize and simplify processes

Technology alone won’t fix fragmentation if your processes remain siloed. It’s important to standardize workflows and data definitions across the company. Ensure every location or department records data in a consistent way that the central system understands. Break down internal silos by establishing cross-functional processes, e.g., sales, warehouse, and transport teams all updating the same system or dashboard for status updates, rather than each using their own tracking sheet.

5. Take incremental steps

Trying to replace all systems at once can be risky and expensive. Instead, mid-sized firms can tackle fragmentation in phases. Identify one high-impact area and integrate that first as a pilot. For example, you might start by combining your warehouse management system (WMS) with your order management system to eliminate manual inventory updates. Once that’s running smoothly and you see the benefits (fewer stockouts, time saved), use that success case to inspire subsequent integration, for example, linking your transportation tracking with customer service portals to provide real-time updates.

6. Train people and adapt the organization

Employees who have long worked in silos or with clunky workarounds need to be trained on new, integrated workflows. Invest in training so staff know how to use the latest systems and trust the single source of data (instead of keeping their own spreadsheets “just in case”). It’s also wise to involve key team members in the integration and skilling planning; they often know the pain points best and can help design better processes.

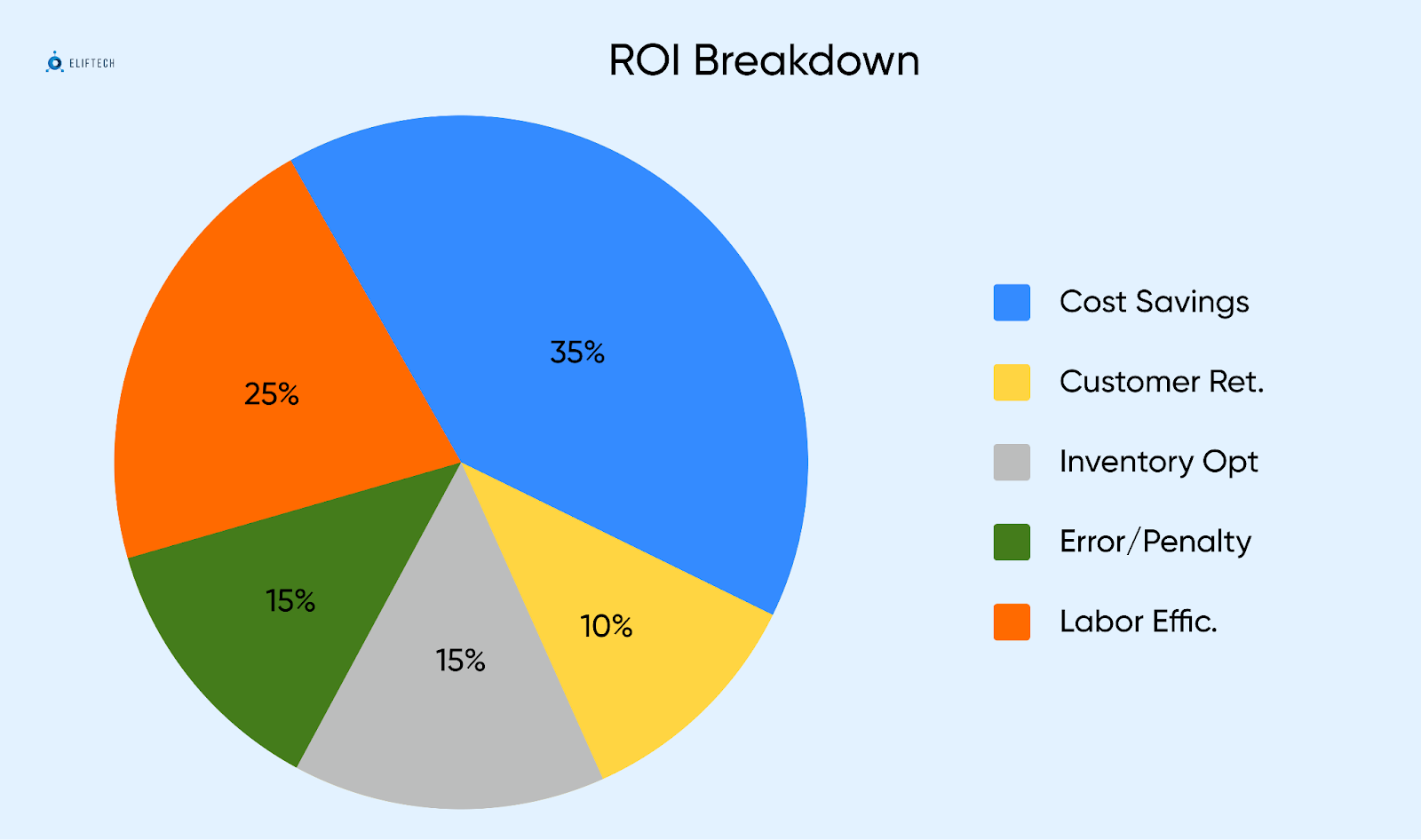

ROI from Integration

Cost savings & efficiency

Modern Transportation Management Systems (TMS) reduce freight costs by approximately 7.5%, resulting in $750,000 in savings on a $10 million budget. Integration eliminates redundant tasks, saving employees 5-10 hours per week, while boosting productivity without the need for extra hires. Unified analytics have driven 55% faster load/unload times and 30% better fleet use, delivering 40% higher delivery ROI.

Error reduction & penalty avoidance

Automated data flows slash human errors in orders, billing, and reduce compliance risks. One carrier cut fuel waste 12%, saving $1.44M annually and achieving a 476% ROI through unified fuel and telematics platforms. Centralized compliance reduces expensive fines and audit risks, a critical safeguard given the $1.6 billion in penalties observed for poor integration.

Inventory & capital optimization

Unified systems reveal inefficiencies, such as 15% excess stock, enabling companies to lower holding costs and free up capital. Better visibility prevents stockouts and overstock, supports revenue retention, and reduces the need for emergency shipping costs. The inventory management tech market has surged, signaling growing adoption of integrated solutions.

Faster decisions & agility

Integrated real-time data enables decisions to be made in hours rather than days, enabling quick responses to disruptions such as port labor strikes or demand spikes. This agility enables the capture of opportunities early, directly contributing to growth and competitive resilience.

Customer retention & growth

Integration improves on-time delivery by 30%, boosting customer satisfaction. Enhanced transparency and service reliability help protect and grow client relationships, a crucial advantage in the tight-margin logistics industry.

Rapid payback

Integration investments often pay for themselves within 6-12 months through low-hanging fruit efficiencies. Industry benchmarks show 7-8% ROI from improved logistics management systems, opening the door to ongoing optimization.

Conclusion

Fragmentation is one of the most silent yet damaging challenges for mid-sized logistics companies. What begins as a few disconnected tools eventually becomes a network of inefficiencies that drains profits, slows decision-making, and erodes staff morale and customer trust.

Mid-sized firms are most exposed to financial waste and compliance risks. They operate with enterprise-level complexity but without the enterprise-level budgets or IT capacity. As a result, valuable data remains locked in silos, and employees waste hours reconciling systems rather than optimizing operations. These inefficiencies can quietly cost millions of dollars each year through lost productivity, excess inventory, and missed opportunities.

Yet, the solution is waiting to be used. Modern cloud-based and modular technologies make integration more accessible than ever. By mapping your processes, prioritizing critical connections, and integrating step by step, everyone can tighten control of their operations.